ISSN: 2319-9873

ISSN: 2319-9873

Department of Electrical and Electronics, Khammam Institute of Technology and Sciences, Jawaharlal Nehru Technological University, India

Received Date: 06/08/2016; Accepted Date: 24/08/2016; Published Date: 26/08/2016

Visit for more related articles at Research & Reviews: Journal of Engineering and Technology

The brushless excitation system works in the absence of commutator, slip rings and brushes. Instead of these components we are using Permanent Magnet Exciter and three phase main Exciter with silicon diode rectifier the system has generated. With this system we can avoid dust particles which cause a great maintenance cost. The complete structure of this excitation system is explained clearly in this review. Drawback of this system is presence of considerable exciter time constant which affects the rate of change of voltage.

Excitation, Alternator, Diode bridge, Slip rings, Permanent magnet, Buck-boost, Multi –contact, Turbo generator

Main Exciter system consists of an alternator Exciter with rotating armature and stationary field. The system includes Permanent magnet Generator with Permanent magnet field to Supply the (Static) field for the (rotor) alternator Exciter [1-3]. The three phase full wave rectifier bridge is used to produce direct voltages for the generator excitation by a rectification process. Thus permanent Magnetic Generator, the armature of the main exciter, and the rectifier bridge are strictly connected to the generator shaft. As these components are all moving with the rotor in the absence of slip rings and thyristor so these are labelled in diagram as rotating elements. But the disadvantage of rotating bridge is the presence of considerable exciter time constant which causes the rate of change of voltage [4].

The voltage regulator [5] measures the out-put or the terminal voltage compares it a set of reference and utilizes the error signal, if any, to control the gate pulses of the thyristor Network [6]. Thus the regulator controls excitation by supplying a buck-boost control [7] signals which ads algebraically to the base setting. The base excitation is controlled by an input setting to the thyristor gating circuits [8]. For base excitation, the control signal is derived from the permanent magnet generator [9].

Brushless Commutation

In all the excitation systems, dc power generated or derived from different means is fed to the generator field through brushes to the slip rings [10]. The brush gear and slip rings are such items that require relatively high maintenance and are a source of failure, thus forming a weak link in this system. This weak link can be eliminated by using the brushless excitation system. With the advent of mechanically robust silicon diode, capable of converting ac to dc at high power levels, brushless excitation system (Figure 1) has been developed [11].

The Brushless Excitation system consists of the following main components

• Permanent magnet pilot exciter or permanent magnet generator (PMG)

• Three phase main exciter.

• Silicon diode rotating rectifier set or rotating diode wheel.

• Automatic voltage regulator.

• Multi contact connector.

• Three phase stator winding of turbo generator set.

• Rotor winding of turbo generator set.

• Quadrature axis measuring coil.

• Slip rings and measuring brushes for field ground fault detection.

In this system permanent magnet pilot exciter and three phase main exciter with rotating rectifier are directly driven from the generator rotor.

In brushless excitation system a common shaft carries the rectifier wheels, the rotor of the main exciter and the permanent magnet rotor of the pilot exciter. The shaft is rigidly coupled to the main generator rotor.

In this system the field of pilot exciter or PMG is a permanent magnet. As this permanent magnet rotates at a speed of 3000 rpm with generator shaft, there is a constant magnetic flux of the permanent magnet and a constant voltage is induced in to the 3 phase stationary armature of the PMG. The output voltage of this PMG is 220V, 3-phase, 400 Hz. This voltage is constant at 220 V as long as the speed of the shaft is maintained at a rated value.

The control rectifier dc output of the voltage regulator is fed to the non-moving field winding of 3-phase main exciter. The voltage regulator regulates the field current of 3-phase main exciter depending upon the excitation power requirement [12].

The 3-phase ac voltage at 150 Hz is induced in the rotor of the main exciter which is fed to the rotating rectifier bridge. The induced 3-phase ac voltage is rectified in the rectifier bridge and fed to the generator rotor winding through the dc leads arranged in certain bore of the shaft via radial bolts. Electrical coupling between exciter-rotor and generator-rotor is made by a special electrical contact system called the "Multi Contact" system. In this system there is no need for brushes. Thus brushes and slip rings are eliminated in this system [13].

In this unit, the arrangement (Figure 2) of the following principal components of the brushless excitation system has been described:

1. Coupling with plug connection

2. Fuse

3. Heat sink

4. Rectifier wheels

5. Diode [14]

6. Magnetic pole of main exciter

7. Main exciter rotor

8. Main exciter stator

9. Slip rings for ground fault detection

10. Bearing

11. Radial-flow fan

12. Exciter enclosure

13. EXCITER DRIER

14. Pilot exciter stator

15. Pilot exciter rotor

16. Foundation

17. Cooler

18. Armature balancing ring

19. Air housing

20. Base frame

21. D.C lead

In all the excitation systems, DC power generated or derived from different means

is fed to the generator field through brushes to the slip ring [15].

The brush gear and slip ring are such items that relatively high maintenance and are a source of failure, thus forming a weak link in this system. This weak link can be eliminated by using the brush less excitation system.

With the advent of mechanically robust silicon diode, capable of converting AC to DC at high power levels, brush less excitation system has been developed [16]. Brush less excitation system consists of the following main components.

In this system permanent magnet pilot exciter and three phase main exciter with rotating rectifier and directly drives from the generator.

In the brush less excitation system a common shaft carries the rectifier wheels, the rotor of the main exciter and the permanent magnet rotor of the pilot exciter. The shaft is rigidly coupled to the main generator rotor.

1. Rectifier wheels with built in diodes.

2. Armature of the main exciter.

3. Ventilation fan.

4. Permanent magnet wheel.

5. Coupling with the turbo generator.

• Rotor of main exciter

• Slip rings for field ground fault detection

• Fan

• Permanent –magnet pole

• Balancing weights

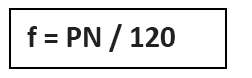

The permanent magnet pilot exciter is of salient pole design (Figure 3). The permanent magnets are mounted on a rotor which forms the pole. The frequency of the voltage produced from this exciter depends upon the speed of the rotor and the number of poles mounted on the rotor by the formula

P = Number of poles

N = Speed of the machine in RPM

f = Frequency of the Machine

The rotors of permanent magnet pilot exciter consist of hub with mounted poles. Ten permanent magnets are housed in a non-magnetic enclosure and this make one pole. There are is number of such poles in this revolving unit.

Use of permanent magnet generator exciter has given the facility of making the system independent from any external supplies. This concept has been found very useful during any ‘black start’ conditions.

The fan is shrunk fitted on the rotor shaft for circulation of cold air into the Exciter and other components.

This is a rotating three phase ac power producing machine. It has a number of poles based on the frequency of which ac power is to be produced.

It is directly driven from the main generator rotor through a solid coupling. Its field coil is mounted on the stator and the 3 phase ac winding is provided on the rotor. The rotating main exciter consists of the following components

Stator field coils, stator field pole, stator frame, exciter fan, air filters, air temperature gauge, ac shaft connection, rotor shaft, dc field supply terminals, generator-exciter coupling, end shield, armature shaft, air temperature measurement probes, collecting troughs, drain from collecting trough485cooling water inlet or outlet, armature retaining ring, armature body, air cooler, magnet frame laminations, main enclosure, drain valve [17].

The field poles and dampers windings are arranged in the stator frame. The field winding is arranged on magnetic poles and damper windings are provided at the pole shoe with the help of bars in order to reduce diode commutation reactance. Between the 2poles, a Quadrature axis coil is fitted for measurement of the exciter current.

The rotor consists of stacked laminations which are compressed by through bolts over compression ring. The three phases winding is inserted in slots of the laminated rotor. After full impregnation with synthetic resin and curing, the complete rotor is shrunk fitted on the shaft.

The second relay system trips the turbo set if the resistance value falls below 5KOhms.

For measurement of excitation current, the principle of development of voltage in the Quadrature axis coil of the main exciter due armature reaction is employed. This voltage is proportional to the excitation current and is measured by placing a coil between the poles.

For this purpose, two Quadrature coils are mounted between two poles on the main exciter stator. Due to flow of current in the armature, and EMF induced on the Quadrature coils. This voltage is taken through leads to the excitation panel on the control room board. As the voltage rises linearly with the current and it is possible calibrate the instrument on the control room board in amperes.

When a machine operates in parallel with a power system, the voltage and frequency will be fixed by the system. The voltage regulator no longer controls the generator output voltage.

The fuel supply to the prime mover which is controlled by the governor determines the power which is supplied by the generator .The generator excitation determines the internal emf of the machine and therefore affects the power factor.

When excitation is increased above the level to achieve nominal no load voltage, rather than the voltage increases, the reactive current (vars) flowing from the generator to the load increases resulting in a lagging pf condition on the generator.

When the excitation is reduced below the level to achieve nominal no load voltage, rather than the voltage decreases, the reactive current (vars) flowing to the generator from the load increases resulting in a leading pf condition on the generator.

The machine speed is determined by the load and fuel supply. The generator voltage is determined by the excitation.

For example, an increase in load will have two effects

1. Speed will initially fall because the energy being supplied by the fuel is less than that required by the load. The speed reduction is detected by the governor which opens the fuel valve by the required amount to maintain the required speed.

2. Voltage will initially fall, the reduction is detected by the AVR which increases the excitation by the amount required to maintain output voltage.

The main advantage of the brushless excitation system is there is no contact between Mechanical and Electrical parts of the system and there is no use of circuit breakers and field breakers. Reduced in maintenance time, outage time, and costs for replacements parts. It provides increased reliability and we can fit various shaft and mounting configurations to match voltage and current requirements.