ISSN ONLINE(2319-8753)PRINT(2347-6710)

ISSN ONLINE(2319-8753)PRINT(2347-6710)

Baskara Sethupathy Subbaiah 1, Deepak Kumar Murugan 2, Dinesh Babu Deenadayalan 3, Dhamodharan.M.I 4

|

| Related article at Pubmed, Scholar Google |

Visit for more related articles at International Journal of Innovative Research in Science, Engineering and Technology

The present study analyses the potential of groundnut shell to produce combustible gas in a fluidized bed gasifier. The goal of the study is to investigate the effects of reactor temperature and steam to biomass ratio on gas composition of the product gas with gas yield. The experiments are performed in the temperatures range of 650°C to 900°C and Steam to biomass ratio of 0 to 1.0. The Equivalence ratio (ER) employed in this study are in the rage of 0.20 - 0.40. Gasification temperature is found to be the most influential factor on the gasification performance. It has been observed that the higher temperature leads to improved the gas yield. It has been found that the yield of methane reduces, and that of carbon monoxide and hydrogen increases as the temperature increases. The experimental results showed that the air -steam fluidized bed gasification of groundnut shell produces gas with HHV of 6.9 MJ/Nm3 at 800 °C and ER of 0.30, A maximum carbon conversion efficiency of 83.4% was achieved at 800 ºC and steam to biomass ratio of 0.30. The maximum cold gas efficiency for groundnut shell was obtained as 71.25 % at steam to biomass ration of 0.8 and the bed temperature of 750 ºC.

Keywords |

| Biomass, Fluidized bed, Gasification, Heating Value. |

INTRODUCTION |

| Biomass is an important in energy conversion processes due to their favorable status with respect to greenhouse gas emissions. However, conversion of biomass into producer gas by thermal gasification broadens the scope of biomass applications [1-2]. Biomass research is recently receiving increasing attention because of the probable waste-to-energy application. Fluidized bed gasification (FBG) is an emerging energy conversion technology for solid and liquid fuels, well suited to low-grade fuels and waste materials. Biomass is potentially an attractive feedstock for producing transportation fuels as its use contributes little or no net carbon dioxide to the atmosphere [3]. Renewable biomass resources include short-rotation woody crops, herbaceous biomass, and agricultural residues. Thermo chemical gasification of biomass is a well-known technology that can be classified depending on the gasifying agent: air, steam, steam–oxygen, air– steam, O2-enriched air, etc [4-5]. Biomass gasification can be classified or studied depending on the gasifier type (moving, fluidized bed, circulating, en-trained), operating pressure (in the gasifier), scale of processing, and also the main gasifying agent used. Besides some unusual gasifying agents, sometimes used at laboratory scale for very specific and academic purposes, the typical agents are air (with some moisture), steam, and steam + O2 mixtures [6]. The technology of biomass air gasification seems to have a feasible application and has been developed actively for industrial applications. Main process products are the producer gas, which is a mixture of mainly H2, CO, CO2, CH4 [7]. Wei et al [8] studied the gasification of pine saw dust with steam as gasifying agent, The effects of steam/biomass (S/B) mass ratio (0.0 –1.0 g/g) and reactor temperature (750–850°C) on the product yields and the compositions of product gas were determined. It was found that the CO and CH4 concentrations decrease with an increase of S/B mass ratio from 0.0 to 0.6 g/g, whereas the CO2 and H2 concentrations increase. Over the range of operating conditions tested, gas yield varied from 1.43 to 2.57 Nm3/kg, gas LHV ranged between 6741 and 9143 kJ/Nm3, Franco et al [9] analyzed the reactions in biomass steam gasification of forestry biomass of Pinus pinaster (softwood), Eucalyptus globulus and holm-oak (hardwood) at various steam/biomass (S/B) ratios from 0.40 to 0.85w/w. As expected, the increase in temperature led to higher gas yields with a reduction in the amounts of char and liquids formed which could be due to further cracking of liquids and enhanced char reaction with the gasifying medium. The authors concluded that the operating temperature was found to have a strong influence on the gas composition. The rise in temperature gave rise to a significant increase in H2 content by 10–20% and a reduction in heavier hydrocarbons by 3 – 5%, while the CO amount decreased slightly in the range 730 and 850 °C and then remained constant. Siyi Luo et al [10] investigated the steam gasification in fixed bed with pine saw dust was used as fuel. The tests were performed at four different temperatures 600 °C, 700 °C, 800 °C, and 900 °C, and the S/B was varied from 0 to 2.80. In each test, the fuel flow rate was kept constant at 5 g/min. The author concluded that, When S/B is 1.43, the dry gas yield and carbon conversion efficiency reach its maximum value with 2.53 Nm3/kg and 92.59% respectively. While if the S / B is regarded as a function of the H2 content, the optimum value of S / B is 2.10. Javier et al [11] studied the gasification of small chips of pine wood in bubbling fluidized bed and studied the effect of gasifying agent on the product distribution. When using steam as gasifying agent, the H2-content in the gas is maximum (around 55 vol %) for S/B ratios of 0.8 - 0.9 kg/kg. The authors' recommendation for the optimum S/B in gasification with steam of 0.9. This high steam content in the gas could be a waste of energy but the steam addition doubles the H2 content in the gas [12]. Lv et al [13] conducted the series of experiments to analyze the air steam gasification of pine saw dust in a fluidized bed. In these tests, steam rate was varied from 0 to 1.8 kg/h. The steam to biomass ratio and equivalence ratio were varied from 0 to 4.04 and 0.19 to 0.27 respectively. From the results the author concluded that the optimal value of ER was found to be 0.23. It is inferred from the literature review that the operating temperature was found to have a strong influence on the gas composition. The steam to biomass ratio was also observed to be an influential parameter on gasification reactions. The present study investigates the effect of bed temperature and steam to biomass ratio on gas composition, heating value and gas yield by the selected biomass fuel of saw dust with air and steam were used as fluidizing and gasifying agents. |

II. EXPERIMENTAL SETUP |

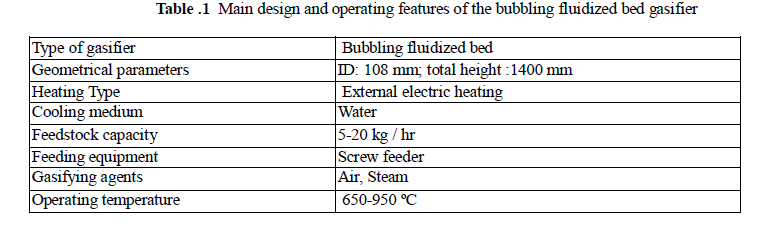

| The schematic diagram of an experimental set up is shown in Fig. 1. The main elements of the installation are : the fluidized bed gasifier, a steam generator, cleaning and sampling system, temperature control system, and the measurement equipment consists of a Siemens make gas chromatograph for gas quality measurement as well as thermocouples and manometer for temperature and pressure control inside the reactor. A fluidized bed system with screw feeder, microprocessor based automatic control unit was fabricated in this work for analyzing the fuel gas behavior and distribution of product yields of sawdust samples. The system consisted of an external electric heater inside the reactor, cyclone, blower, water scrubber, burners and dry filter, a Cr-Al (K type) thermocouples, and microprocessor based automatic control unit with temperature indicators, PID (Proportional–Integral–Derivative) controller, heating rate and temperature setting unit. The gasifier unit detail describe in Table 1. The product gas from the gasifier was made dust – free and cleaned by passing it through a gas cleaning and cooling system before it was being put into gas analyzer. The hot fuel gas from the fluidized bed gasifier was made to pass through a cyclone to remove the larger particles. After passing through the cyclone, the gas still contained dust particles and tar and hence, it is further cooled and cleaned by passing it through a water scrubber and dry filter. The dry and clean product gas was then analyzed in a gas analyzer to measure the composition of CO, CO2, CH4 and H2 presence in the fuel gas. |

|

|

| The details of components of the bubbling fluidized bed gasifier which have been developed are explained here. Gasifier: The bubbling fluidized bed vessel used for the gasification experiments is made of stainless stell. The gasifier is a 0.108 m inside diameter with a length of 1.4 m. The producer gas out let pipe comes out from the top of the gasifier. The gasifier is fitted with a single perforated type distributor plate at the bottom. The stainless steel gasifier vessel is placed inside an electric furnace such that its surface could get maximum exposure to heating coils for better heat transfer. The gasifier temperature was controlled using a thermocouple with a control panel system. The temperature measurement was carried out with Ni-Cr-Ni thermocouples. The control of gasifier temperature is very important to avoid problems resulting from the agglomeration of the ash and bed materials, and subsequent blockage of flow through the system. The ash from the reactor was disposed off periodically through a lock hopper arrangement. |

| Biomass feeding system: The biomass feeding system consists of two screw feeders with a hopper, the upper feeder is connected to a variable speed drive system that controls the fuel feed rate and supplies the same to the lower screw feeder. The feed was calibrated with rpm of the drive motor. This lower feeder, attached to the gasifier through a feeding port at the height of 0.125 m above the distributor plate, was maintain at a high speed to avoid pyrolysis of biomass inside the screw feeder. This high speed screw feeder pushes the biomass materials instantaneously into the bottom dense region of the fluidized bed. A lock hopper arrangement is located on top of the upper feeder which was filled from the storage of fuel after certain intervals of time during experiment. The mass flow rate of biomass fuels was maintained at the desired operating conditions. Gas cleaning and cooling system: The product gas from the gasifier was made dust – free and cleaned by passing it through a gas cleaning and cooling system before it was being put into gas chromatograph for gas analysis. The hot fuel gas from the fluidized bed gasifier was made to pass through a cyclone to remove the larger particles. After passing through the cyclone, the gas still contained dust particles and tar and hence, it is further cooled and cleaned by passing it through a water scrubber and dry filter. Gas flow measurement system: An orifice plate was positioned on the duct between dry filter and suction blower to measure the gas production rate of the fluidized bed gasifier. The pressure drop across this plate was measured using a differential pressure micrometer and this pressure drop was then used to estimate the flow rate of the gases through the orifice plate |

III. MATERIALS AND METHOD |

| The sample of biomass used in this study was groundnut shell which was procured locally in Thiruvallur near Chennai, Tamilnadu, India. Groundnut shell sample was dried naturally in air and milled. The components and elements present with the samples and properties are illustrated in the Table 3.4. The HHV and moisture content (wet basis) of the sample are 16.91 MJ/kg and 11.12 % respectively. India is the second largest producer of groundnuts after China. Groundnut is the largest oilseed in India in terms of production |

|

| The electric furnace was turned on to preheat the fluidized-bed reactor; meanwhile, steam generator was turned on for the preparation of steam for the test. After the bed temperature reached the desired level and was kept steady, the air blower was turned on the air was introduced at the bottom of the reactor vessel through the distributor to keep the bed in a fluidized state When the bed temperature again turned steady, the screw feeder was turned on at the desired rotate speed and the test began. Typically, it took 30 min for the test conditions to reach a stable state. Five samples were taken at an interval of 5 min after the test ran in a stable state. This state was continued until the reactor temperature could reach about 600º C. The raw biomass material was then fed through the screw feeder into the chamber. The feed rate of biomass was controlled by a variable speed motor drive. The supply of air was gradually stopped and the superheated steam at 200º C was introduced at the bottom of the reactor vessel. The bed was operated in fluidized condition with air as fluidizing medium. The gasifier temperature was controlled using a thermocouple with a control panel system. |

IV. EXPERIMENTAL RESULTS |

A. Effect of Temperature on gas composition |

| The variation of gas composition with bed temperature during the gasification of ground nut shell is analyzed. The temperature of the reactor is varied from 650 to 900°C and the corresponding producer gas composition is noted. From Figure 2, The test results were shown in Table 4. It can be seen that the concentration of H2 and CO are increases gradually with increase in temperature from 650 to 800oC and then decreases after that. The concentration of CO2 and CH4 decreases with increase in temperature. The concentration of hydrogen and carbon monoxide is lower because of the less percentage of volatiles present in the biomass and more amount of moisture content in it. The composition of CH4 varies between 3.80 to 4.92 % and the concentration of H2 is found to be in the range of 20.0 to 20.95 %. The concentration of CO lies in the range of 19.9 to 17.6 % and the concentration of CO2 lies in the range of 14.7 % to 12.9 %. The experimental conditions and data of bubbling fluidized bed gasification of groundnut shell against temperature at fixed steam biomass ratio of 0.30 and biomass feed rate of 15 kg/h are shown in Table 3. These results are in good agreement with other published experimental observations by Karmakar and Datta [14]. |

|

|

B. Effect of Steam to Biomass ratio on gas composition |

| The effect of steam/biomass ratio on gas composition obtained by the gasification of groundnut shell is shown in Figure 3. The test results were shown in Table 4. There was a significant decrease in CO concentration up to steam/biomass ratios of about 0.6, and at higher values of this ratio, no significant changes were detected. A similar situation occurred with hydrocarbons release, though extent of decrease in concentrations was much smaller. No significant changes were observed for CO2 amounts. The formation of H2 seems to be favored for steam/biomass ratio of about 0.6 – 0.7 w/w, as maximum values were obtained for this range. |

|

| The similar trends were reported by the other researcher Corella et al [15] for the same ranges of steam/biomass ratio and similar temperature. |

|

C. Effect of Temperature on Gas Yield |

| The gas yield is the volume of dry fuel gas generated in Nm3 per kg of fuel. Its variation with bed temperature is shown in Fig.4. As the temperature increases, more of the solid fuel is converted into gaseous products thereby increasing the product gas yield. |

|

V. CONCLUSION |

| In this research work, a fluidized bed gasifier made of stainless steel tube with inside diameter of 108 mm and a height of 1400 mm, extending into a 300 mm inside diameter and 450 mm high expanded freeboard section was fabricated with cleaning and cooling system of cyclone, water scrubber and dry filter. A drilled holed distributor plate of 115 mm ID and 200mm OD was used for air distribution. The present lab scale model can gasify groundnut shell with the range of 4 to 18 kg/h with the optimum value of 10 kg/h. From the analysis of the two critical parameters (temperature, steam-to-biomass ratio). The temperature plays a significant role in the process. A higher temperature will be more favorable for gas and hydrogen yield. A too-high S/B will lower reaction temperature, and then will cause hydrogen yield to decrease. There exist optimal values for S/B. In the present work, the optimal value of S/B was found as 0.50. The highest hydrogen yield per kg of biomass is achieved at the condition of temperature 800°C, S/B of 0.60 and equivalence ratio of 0.20. It is shown that under proper operating parameters biomass air - steam gasification in a fluidized bed is one effective way for the generation of hydrogen-rich gas. |

NOMENCLATURE |

|

| S / B steam to Biomass ratio |

ACKNOWLEDGMENTS |

| The authors are deeply grateful to Mr.M.V. M.Velmurugan, CEO, Velammal Educational Trust, Velammal Engineering College, Chennai, India, for providing financial support for our experimental work (letter no.HR/VEC/09/10). The authors are also grateful to Mr.V.Durai swamy, Swamequip, Chennai, for his help with the fabrication of the system components and with performing the experiments. |

References |

|