ISSN: 2321-6204

ISSN: 2321-6204

Asim Shabir*

National Institute of Food Science & Technology, University of Agriculture, Faisalabad,Pakistan, ZipCode-38000.

Received date 16/12/2015; Accepted date 23/03/2016; Published date 29/03/2016

Visit for more related articles at Research & Reviews: Journal of Food and Dairy Technology

This study was conducted to evaluate the process line and quality of cooking oil and vanaspati ghee manufactured in Madni ghee mills (pvt) Ltd. in Pakistan. The commercially available brands were investigated for free fatty acid, peroxide value, smell, weight, color, rancidity, foreign matter,appearance and cold point. Analysis showed that free fatty acid, peroxide,smell, weight and rancidity value significantly same as standards set by Pakistan standard quality control authority (PSQCA). These results confirm the product development under the hygienic conditions and quality limits sets by Pakistan standard quality control authority.

Cooking oil, Quality evaluation, Pakistan, Ffree fatty acid, Color.

Madni oil industry is situated in 32 Km Sheikpura road. It is reputed and a leading name in vegetable ghee, cooking oil and soap products. The organization manages the process of vegetable ghee, cooking oil, tin packaging and printing and laundry and toilet soap within existing premises.

Madni Ghee Mills (Pvt.) Limited having production capacity of vegetable ghee as 24000 Metric Ton, cooking oil 20000 Metric Ton and laundry soap 24000 Metric Ton on per annum. Its products are registered with defense forces, utility stores corporation and canteen stores department of defense forces. Where its supplies are successfully being supplied and many contracts of vegetable ghee, cooking oil and laundry soaps have already been successfully completed and few in pipelines. The unit is registered with Pakistan Vanaspati Ghee Manufacturing Association, Chamber of Commerce and industry, Sales Tax Department Government of Pakistan, Pakistan Army, Navy and Trade Marks Government of Pakistan [1].

Technical staff of Madni Ghee Mills (Pvt.) limited is highly experienced and well educated in this field. The unit comprised upon 74 Kanal 04 Marla’s and 165 sq. ft of land, which is equipped with unique type of latest machinery and plant installed in its attractive building. The beautiful roadside Mosque, fruity garden on the front side of the office block creates extra ordinary beauty [2]. Private energy source, Gas connection and sewerage line linked with disposal drain are in existence within premises of the mills.

The people who are dealing in vegetable ghee, cooking oil and laundry soap they know well the name of madni ghee mills renowned products, which are in the market with the name and style of “Madni banaspati, Madni cooking oil and Madni laundry soap.

Considered Brands for Comparision

The industrial brands and products which were considered for this analysis were Pakwan cooking oil,Madni cooking oil and Madni banaspati.

Considered Factors for Comparision

During this study the following factors were considered for the comparison and analysis.

Set-up of Industry

Industry set-up tremendously has impact on everything an industry is part of. The parameters which were accounted for this study were Administration block,Oil refinery,Neutralizers,Bleachers,Deodorizers,Autoclaves,Filter press,Coolers,Hydrogenation plant,Quality assurance lab,Steam boiler unit,Soap preparation plant,Filling unit,Work shop,Tin printing unit,Raw oil storage tank,Water storage tank,Caustic soda tank and Centrifugal pumps.

Additionally it was noted that, There are two Boilers with a capacity of 250 Pounds each. The Boilers are wet heat energy source in the form of steam [3,4]. This heat circulates in all the heating coils of processing units. Its input is water treated with softening chemicals (NaCl, Aqua Prime) and output is heat energy in the form of steam. The maximum temperature is 205OC.

Gas Cracking Plant

The requirement of Hydrogen (H2) Gas is met through the production of gas by the Gas Cracking Plant using Natural Gas as raw material by cracking Methane (CH4). CO2 is the bye-product.

Receiving and Storage of Raw Oil

The raw oil is imported from Malaysia, Indonesia, America and Brazil. It is transported to the factory through lorry tankers and is stored in storage tanks. Usually Cottonseed oil, Canola oil, Sunflower oil, Soybean oil and R.B.D. Palm oil are used for manufacturing of ghee.

Policies of Madni Ghee Mills (Pvt) Limited

Quality and consumer safety policy: Madni ghee mills take care to ensure that their customers & consumers are provided with the best quality products that are safe in use. To meet the customer’s expectation and needs. Madni ghee mills is committed to develop and ensure consistent supply of affordable, convenient, safe and high quality products. As a service company we take care to ensure that our customers are provided with the best quality services to fulfill all customers needs [5,6].

In order to achieve these goals Madni ghee mills maintains quality and consumer safety objectives along with implementation plans on annual basis and maintain follow up by reporting process. The organization design, operate and maintain processes and plants to establish and maintain standards and procedures for the control and monitoring of all operations that prevent potential product safety hazards [7]. It ensures the compliance with applicable legislation and set standards. The authority introduce appropriate product quality management system and maintain HACCAP as a management tool at all their operation.

Helping their suppliers to develop their quality process and standard so as to get consistent quality suppliers and develop supply chain to improve overall quality performance audits is followed under the strict regulation under the organization. Responsibility to implement this policy lies with general manager & the same is filtered to the functional heads and respective managers in their areas of responsibility.

Environmental policy: Madni ghee mills is committed to meet the needs of the customers and society in a sound environment and sustainable manner. The organization is working in co-operation with members of industry, government bodies and public interest groups, scientists, environmentalists, technical department and customers to promote achievements of high standards of environmental care through multiple aqpproaches [5,7]. The organization is continuously striving to reduce the wastage, conserve energy, examine reuse & recycle throughout the operation. They are also ensuring that all the employees are aware of the company environmental policy and are motivated to apply it in their respective sector. Apart from these, the organization is considering to ensure the safety of their product manufacture at their side & continuing monitoring and reporting all progress and notifying the environmental associated issues on regular basis.

Refining of vegetable oils in simple terms means “Removal of Impurities”. Major impurities in the oils may be mentioned as follows: Dirt and other foreign matters to the seeds, solid matters from the seeds, mucilage, free fatty acids, coloring matters, substances imparting taste and smell to the oil and moisture.

Refining eliminates all the impurities [3,8]. The process employed in refining is comparatively simple. If the raw material from which oil is extracted is clean, dry and sound the oil produced is of good quality while oil obtained from inferior, unsound oil seeds contain more impurities. The processes employed in refining are either mechanical, chemical, or combination of two.

Following steps are involved in manufacturing of cooking oil and vegetable ghee (Figures 1 and 2).

Pre-Neutralization

Pre-neutralization is carried out in a vessel called pre-neutralizer. It is cylindrical in shape and has electric motor for centrifugation of oil. Motor has steering shaft with baffles for complete mixing of contents. It has steam heating coils and caustic soda washing coils [8-10]. Temperature gauge is also mounted on it. Generally the process of pre-neutralization is completed in 7-8 hours.

The objective of pre-neutralization is the removal of free fatty acids. Oils have 2-2.5% free fatty acids. It has to be reduce it to 1-1.5%. PSI (Pakistan Standard Institute) recommends 0.20 - 0.25% free fatty acids. Due to removal of F.F.A. the color of oil is improved. Usual method of removing the free fatty acids is to treat the crude oil with Sodium hydroxide solution carefully regulated in strength and amount, and at carefully regulated temperature. Firstly free fatty acid percentage of crude oil is determined and then NaOH of required Baume is added. Generally NaOH of 20-22 Baume is used[11,12]. Then crude oil is charged in to the preneutralizer and it is centrifugally moved with the help of electric motor. The temperature of oil is raised up to 70oC with the help of steam heating coils. When required temperature is achieved NaOH of 20 - 22 Baume having 70°C temperature is added to crude oil with the help of caustic soda washing coils, it is thoroughly mixed for 10-15 minutes. The soda solution combined with the free acids turned of soap. After this it is given one-hour rest. During rest soap settles in the bottom and oil becomes on upper side. The soap is drained through the drain valve mounted at the bottom of vessel. Then the oil is washed with water having 100°C temperature. Water dissolves soap and free alkali and settle down oil comes on upper side. It is given 1-hour rest and the water is drained through drain valve.

Oil sample is taken to check free fatty acid percentage up to 0.25% or less. Soapy particles should not be present. If soapy particles are present then oil, again washed with water and given 1 hour rest. The number of water washing depends upon nature of oil e.g. cotton seed and soybean require three washer, canola requires two washer. Pre-neutralized oil has 0.25% or less F.F.A.%. Madni Banaspati has 0.08% F.F.A.

Following tests are applied at pre-neutralization stage: F.F.A % test prior to processing, F.F.A % test after processing, Soap test. After the tests, the pre-neutralized oil is then passed to pre-bleacher for bleaching. Amount of caustic soda required to neutralize free fatty acids is 9 Kg of solid NaOH. It is required to neutralize 0.4% F.F.A in a Batch of 16 tons.

Pre-Bleaching

Pre-bleaching is carried out in a vessel called pre-bleacher. It is cylindrical in shape and vertical in direction. It has an electric motor having steering shaft with baffles for centrifugation of pre-neutralized oil [12-14]. It has temperature gauge, vacuum gauge , pressure gauge and steam heating coils for raising temperature of input oil. Generally the process of pre-bleaching is completed in 3-4 hours.The objective of pre-bleaching is to get rid of unwanted pigments and coloring matters from input oil. Bleaching is done by means of bleaching earth (Clay+silica dioxide, mixed in certain proportion and ground to particle size of 250 micron and acidified with HCl). It contains 3-4% moisture known as Fuller’s earth. First pre-neutralized oil is charged in to the bleaching vessel and stirring is started. Then it is warmed and dehydrated under vacuum at 120 °C to remove water and free air. It takes 1-2 hours for complete dehydration. After this, the oil is cooled to lower down its temperature up to 110 °C. Later on, the bleaching earth is considered at recommended rate depending upon the intensity of color of oil as below is carried out.

• Palm and palmoline = 2 Kg/ton of oil.

• Soybean and canola = 5 Kg/ton of oil.

• Cotton seed = 8 Kg/ton of oil.

The amount of bleaching earth is doubled in case of cooking oil. 75% of bleaching earth is added in pre-bleacher & rest of 25% is added in post-bleacher.

The process consists of thoroughly stirring the dry absorbent powder into the oil when gently heated under vacuum status. Activated carbon at the rate of 100 g/ton is also added in case of cottonseed oil, to bleach the darker color of cottonseed oil. Fuller's earth is mixed slowly so that every particle of the oil combines with every particle of the earth. Stirring continues and that the whole process takes about an hour. Fuller’s earth removes all the impurities and color, and makes the oil fine. It also absorbs any particle of soap that is left behind. Explanation of the matter lies in the fact that the coloring substances, which pass from the seed into oil, is absorbed and held back by earth. Maintaining the input oil temperature at 100°C ± 05 °C. Bleached Oil is filtered the through filter press. It removes the bleaching earth and clear oil is obtained. The color index of bleached oil is measured with the help of spectrophotometer / tintometer. Following tests are applied at this stage:Color index R,Y,F.F.A%. The pre-bleached oil is then passed to converter for hydrogenation[14-16].

Hydrogenation

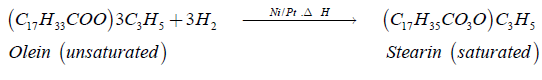

Hydrogenation or hardening may be defined as a process whereby part or in some cases nearly all the unsaturated acids in an oil are caused to combine with hydrogen under the influence of a catalyst. In this way the glycerides of the unsaturated acids are converted into the saturated acids of another series. Thus in case of olein which is unsaturated, the addition of 6 atoms of hydrogen produces stearin, which is saturated in accordance with the following formula:

Out of the many processes, which has been suggested with the objective of converting liquid oils into solid fats, hydrogenation is the only one, which has been applied on large commercial scale [17]. When it is considered that only 0.68% of H2 by weight is necessary to convert olein into stearin and how great is the change brought about in a simple manner by so small addition. By volume 30 feet3 of hydrogen is required for each percent reduction in iodine value of per ton of oil [11,16].

Hydrogenation is carried out in a vessel called converter or autoclave. It is completely airtight vessel and has heating coils, steering shaft having baffles, perforated hydrogen coils, compound gauge to measure pressure and vacuum and temperature gauge to measure temperature[18]. Generally the process of hydrogenation is completed in 6-8 hours.

First the vessel is filled with neutralized and bleached oil. It is dehydrate it up to 170o C temperature under vacuum for 1-½ to 2 hours. If water is present then it will poison nickel and which effect its quality. After this hydrogen gas is applied through perforated hydrogen coils under vacuum and thoroughly mixed by continues stirring. Now food grade Nickle catalyst (G-53, Germany) is added in recommended quantity as follow: 1100 grams/ton for palm oil(1), 2250 grams/ton for soybean oil, and 2200 grams/ton for sunflower & cottonseed oil.

Hydrogen gas is applied continuously and samples are drawn for the inspection and testing of melting point. Desired/ approved/recommended melting point for Banaspati ghee is 36 ± 2 °C. When approved melting point is achieved then hydrogen gas is stopped. After this, the converted product is cooled up to 100-110°C. Then product is filtered through filter press. It removes Ni catalyst and clean, clear oil is obtained. The product may not be cooled below 90°C otherwise it will create problem in filtration. Again melting point is verified after filtration. Hydrogenation is not carried out in manufacturing of cooking oil[19,20].

The extent to which an oil has been hydrogenated, is measured by the fall in iodine value, which the oil has undergone, since it is directly proportional to the amount of hydrogen gas, which has been added to the oil. F.F.A% increases during hydrogenation. As hydrogenation proceeds and the unsaturated bodies become saturated, the fall in iodine value is coincident with a steady fall in refractive index and rise in melting and solidifying points.

This can be verified as: =140.2

Iodine value of cotton seed oil at charging = 140.2

Iodine value of cotton seed oil before gas passing = 95.8

Iodine value of cotton seed oil after complete hydrogenation = 71.69

Following tests are applied at this stage:Melting point,Color index Red, Yellow,F.F.A percentage and Iodine value. The hard oil is then passed to post-neutralizer for post-neutralization.

Post-Neutralization

Post-neutralization is carried out to remove the soap and Ni catalyst if it is present due to poor filtration. Firstly hard oil is charged into post-neutralizer. The temperature of hard oil is maintained at 90 ± 5oC by heating or cooling. Its free fatty acid percentage is calculated and caustic soda is added accordingly. Generally caustic soda of 8-10 Baume is added without any agitation, light wash of water is given. After this 2 hour rest is given, due to rest soap settles down at the bottom and oil becomes on upper surface. The soap is drained through the drain valve present at the bottom of vessel.

Now two washes of boiled water are given. After 1st wash give 1 hour rest, drain soap and water through drain valve. Then 2nd wash is given and same process is repeated. Apply soap test, it should be negative. If it is positive then 3rd wash is given. Generally the process is completed in 5-6 hours. Following tests are applied at this stage:F.F.A percentage prior to neutralization,, F.F.A percentage after neutralization and Soap test.

Post-Bleaching

Post-bleaching is carried out in a vessel similar to that used for pre-bleaching. First post-neutralized oil is charged into post-bleacher and its temperature is raised up to 110 °C. It is completely dehydrated under vacuum and stirring is continued throughout the process. When complete dehydration is achieved then bleaching earth is added in recommended quantity. It is thoroughly mixed in oil for 45 minutes. At the end post-bleached oil is filtered through filter press to remove the bleaching agent from oil. Generally the process is completed in 3-4 hours. Following tests are applied at this stage:Color index Red,Yellow, Melting point and F.F.A percentage. The post-bleached oil is then passed to deodorizer for deodorization.

Deodorization

Deodorization is carried out in cylindrical vessel. It is completely air tight and vertical in direction. It has open steam lines, steam heating coils and low and high vacuum system. Steam pressure, temperature and vacuum gauges are mounted on it. Electric motor with steering shaft having baffles is not present. A fat catcher is present to catch volatile matters. Generally the process is completed in 7-8 hours.

Deodorization is a process of steam distillation whereby relatively volatile odoriferous and flavored substances are stripped from the relatively nonvolatile oil. The operation is carried out at a high temperature to increase the volatility of the odoriferous components. The application of reduced pressure during operation protects the hot oil from atmospheric oxidation, prevents undue hydrolysis of oil by steam and greatly reduces the quantity of steam required. The objective of deodorization is removal of unwanted odors, odoriferous matters and other volatile fatty materials and to improve smell, odor and taste of finished product. Some of compounds responsible for tastes and odors of oil are ketones, terpenoids and aldehydes. Flavor and odor removal generally parallels free fatty acid removal. The concentration of odoriferous substances in oil is generally quite low. In case of cottonseed, soybean, tallow and peanut oil, it does not appear to be greater than 0.10%. Deodorization also reduces the color of oil and destroys peroxides in oils. The process of deodorization is influenced by temperature, vacuum, steam and design of deodorizer. Generally the process is completed in 8 hours in case of ghee and 12 hours in case of cooking oil.

Firstly post-bleached oil is charged into deodorizing vessel. Oil is warmed and dehydrated up to 170°C under low vacuum status to remove moisture. When the oil is completely dehydrated and required temperature is achieved, then the process is boosted up to high vacuum status along with increase in temperature to 190 ± 10°C. Now citric acid is added at the rate of 100grams/ton of oil. 50% of citric acid is added before application of live steam and rest of 50% is added before cooling. Citric acid helps in removal of volatile matters and increase shelf life of final product. The process is assisted with treatment of oil with live steam for 3-4 hours. Samples are drawn for sensory evaluation and tests are also applied for justification of deodorization. When the product is free from bad odors the live steam is stopped and product is cooled down up to 140 °C. Now it is shifted to cooling vessel (cooler) for further lowering down of temperature to 70 °C. Cooling is done under vacuum to avoid oxidation and to remove water. After this it is filtered through filter press and passed to churns. Following tests are applied at this stage:General appearance,Odor/smell,Taste,F.F.A. percentage,Rancidity,Moisture,Soap test,Melting point,Peroxide value and Color index.

In case of Cooking Oil Hydrogenation, Post Neutralization & Post Bleaching are not performed.

Blending (Addition of Vitamin A&D3)

Completely deodorized product after filtration is taken into filling churns. Here vitamin A&D3 are added in recommendedquantity/ dose. Vitamins are imported from Germany (Merck). (BASF).Generally 33 ml of vitamins/ ton of the product are added and thoroughly mixed by continuous stirring. Samples are drawn for vitamin confirmation test, the vitamin test should be +ive. Now it is ready for filling and packaging [9].

Filling/Packaging

Product is cooled up to 50 ± 5°C. Now it is manually/mechanically/automatically filled in food grade approved packaging material. Automatic filling is carried out in case of pouches. The Prepack Click 2 machine is used for automatic filling and it fills 2000pouch of 1.0 Kg size/hour and 2400 pouch of ½ Kg /hour. After filling tins/buckets/pouches are properly sealed. The products are packed into different pack mix for marketing as detailed below:

Vegetable Ghee

• 16 Kg. Tin and Bucket

• 05 Kg. Tin and Bucket

• 2.5 Kg. Tin and Bucket

• 01 Kg. Pouch pack

• ½ Kg. Pouch pack

• ¼ Kg. Pouch pack

• 05 Kg. Pouch Pack

Cooking Oil

• 16 Letters Tin

• 10 Letters Plastic Can

• 05 Letters Pet Bottle

• 05 Letters Pouch Pack

• 05 Letters Tin

• 2.5 Letters Tin

• 03 Letters Pet bottle

• Letter Pouch pack

Chilling: When a fat is allowed to cool slowly without any agitation, then it sets up grain. After packaging ghee is gradually chilled in chilling rooms, which are made of insulating material to maintain the temperature of chilling room. Ammonia compressed air conditioning machine is used for this purpose.

The chilling process of vegetable ghee is completed in 18-22 hours in summer& 8-10 hours in winter and temperature of 8-9°C is maintained in chilling room. After chilling ghee is stored in ware houses at room temperature and is ready for consumption.

There are 5 steps in soap manufacturing:-

Soap Grain Mixing Pan

It is cylindrical in shape, fitted with separate lines for induction of caustic soda and water. Soapy matters are transferred in pan from neutralizer, cutting wastes and fats from the deodorizers. After charging, H2O is added to convert it in liquid form. After this caustic soda of 50 Baume in recommended quantity is added, it is heated till the required texture is achieved, which almost depends upon experience[1].

Soap Boiling / Boiling and Mixing Pans

These are large pans and have capacity of 3–4 tons. In this soap is heated for 7–8 hrs. Till water is evaporated and soap grains becomes smaller.

Crutching and Mixing Tank

It is cylindrical in shape and has capacity of 5 tons. Soap is manually filled in it with the help of tins from the boiling pans. After filling 60 to 75 kg of soap stone mixed in 15 tons of oil is added. Sodium Silicate , 120 to 150 kg is added. Subsequently, 2 tons of Resin are added. All the material is thoroughly mixed for 1 hour. It has baffles for mixing. Steam heating coils are present for heating. After completion of the process one-hour rest is given to settle.

Convertion in Iron Frames

From crutching tank soap is filled into iron frames to convert it in blocks.

Cutting and Packaging

Soap blocks are stored for 24 hrs. to reduce moisture. Cutting is carried out with the cutters to convert the blocks in cakes of different sizes which are packed in cartons of 9 kg capacity.

At last it’s concluded that every step of ghee and oil processing from receiving of crude oil till packaging of final product is carried out under hygienic conditions. All the rules and regulations not only related to food safety but also related to safety of the employees are followed strictly. From these results it is proved that quality of Vanaspati ghee and cooking oil available in Pakistan according to the standards set by PSQCA. The values of free fatty acids, nickle content and peroxide are significantly low as compared to standard values. Healthy and nutritious Vanaspati ghee and cooking oil is available for consumer.

Internship duration of 10 weeks make a lot of contribution in my practical knowledge related to processing of vegetable oil.