Page 96

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

Fibers made by centrifugal spinning technology

Jana Hlavata

and

Eva Kuzelova Kostakova

TU Liberec, Czech Republic

C

entrifugal spinning, Forcespinning¬TM or rotary jet spinning, all these names represent relatively new and simple technology

that allows production of fibers by using only centrifugal forces. These forces are caused by high-speed rotation of the spinneret

unit and are necessary for drawing polymeric jet and fiber formation. Two main ways of centrifugal spinning process depend on type

of the spinneret unit. These are needle and needle-less technology. Besides that, it is possible to combine centrifugal forces with electric

field to produce fibers by electro-centrifugal method. Fibers could be forming from solutions or melts as well. Centrifugal spinning

has several advantages in comparison to electrospinning such as spinnability of liquid form of materials (polymeric solution/melt,

ceramic, metal), larger range of spinnable materials (no requirements on conductivity of material) and higher production rate. Fibers

are arranged in one direction and gathered on collector. This homogenous fiber layer could be used in many different applications, I.e.

in biomedical area, tissue scaffolds, drug delivery systems, filtration, energy industry etc. Materials polycaprolactone (PCL), polyvinyl

butyral (PVB), polyamide 6 (PA 6), polyvinyl alcohol (PVA), copolymer of polycaprolactone and lactid acid (PLC), collagen and

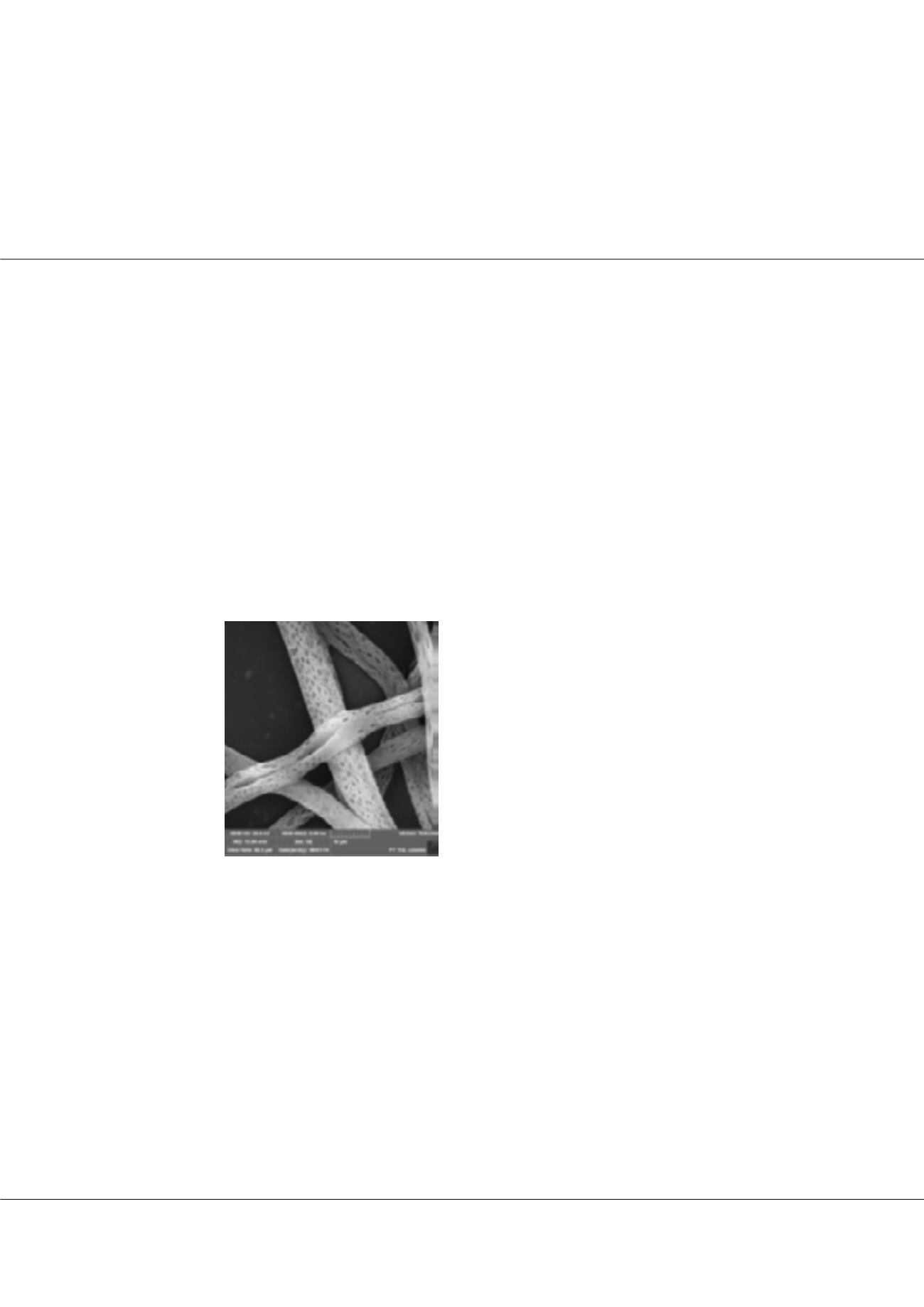

other have previously been successfully spun. Forcespun fibers generally have wide distribution of their diameters. Big variability in

spinning devices, used materials and process conditions lead to production of modified fibers, such as porous fibers, bicomponent

fibers and even hybrid and inorganic fibers.

Biography

Jana Hlavata is Ph.D. student at Department of Nonwovens and Nanofibrous Materials, Faculty of Textile Engineering at Technical University of Liberec, Czech

Republic. She specializes in centrifugal spinning technology, especially in needle and needle-less way. Materials and modified fibers mentioned above have been

successfully spun at two devices assembled at department. These devices are improved and upgrade according to her specifications and requirements. During her

internship at University of Alabama at Birmingham she has been dealing with controlled morphology of porous fibers

jana.hlavata1@tul.czJana Hlavata et al., Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-006

Figure1

SEM picture of porous fibers made from PCL

solution by needle-less way of centrifugal spinning

technology. Fibers were produced at Department of

Nonwovens and Nanofibrous Materials at Technical

University of Liberec. Scale is 10 μm.