Page 42

Notes:

conferenceseries

.com

November 13-15, 2017 | Las Vegas, USA

14

th

International Conference and Exhibition on

Materials Science and Engineering

RRJOMS | Volume 5 | Issue 7 | November, 2017

Microstructural characterization of Mg-SiC nanocomposites produced by powder metallurgy techniques

Daniela Penther, Sepideh Kamrani, Alireza Ghasemi, Ralf Riedel

and

Claudia Fleck

Technische Universität Berlin, Germany

I

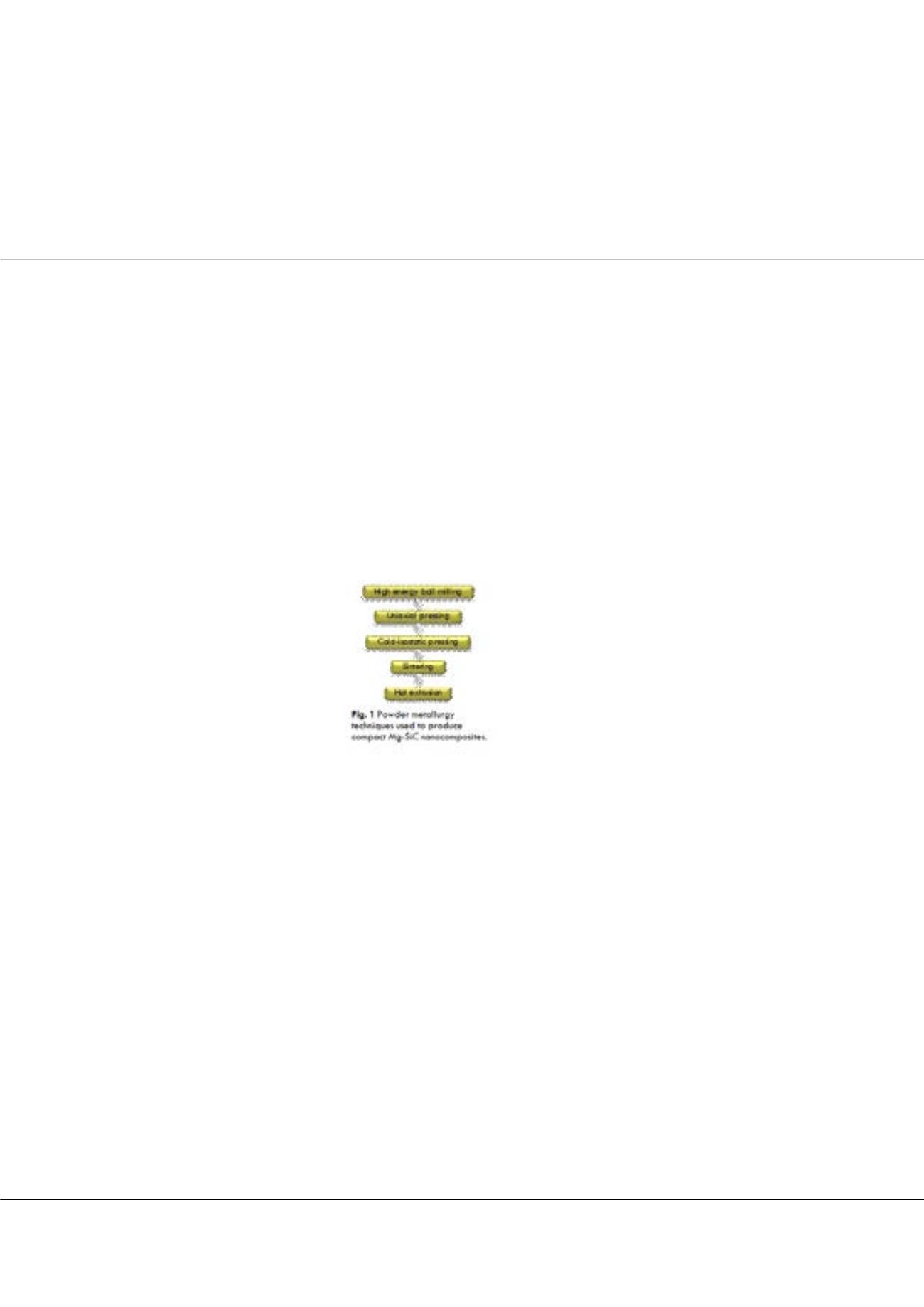

n the present study, the microstructure of newly developed magnesium matrix composites reinforced with SiC nanoparticles was

investigated. To produce Mg-SiC nanocomposites, magnesium powder and various volume fractions of SiC particles with an

average diameter of 50 nm were co-milled by a high energy planetary ball mill. The milled powder was compacted by a hydraulic

hand-operated press followed by cold isostatic pressing and sintering. Finally, the nanocomposites were hot extruded to eliminate

porosity and achieve full density. Scanning electron microscopy, energy dispersive x-ray analysis and x-ray diffraction were used to

characterize the microstructure and texture of the magnesium matrix and the distribution of the SiC-reinforcements after extrusion.

Further, transmission electron microscopy analyses were performed to study the grain size of the magnesiummatrix and the interface

between the SiC nanoparticles and the magnesium matrix. All developed nanocomposites revealed a uniform distribution of the

SiC nanoparticles in the magnesium matrix. No evidence of porosity or interfacial products between the SiC nanoparticles and the

magnesium matrix were found, indicating a well-bonded interface. The used powder metallurgy techniques allow to produce dense

nanostructured Mg-SiC nanocomposites.

Biography

Daniela Penther has her expertise in powder metallurgy techniques including high energy ball milling, diverse pressing techniques and sintering of metals. She started

studying and analyzing composites by SEM (EDS, EBSD), XRD and TEM during her diploma thesis in the collaborative research centre “TRIP-Matrix-Composite” supported

by German Research foundation (DFG) at TU Bergakademie Freiberg, Germany. During her PhD she is currently producing Mg-SiC nanocomposites by powder metallurgy

techniques and analyzing their microstructure as well as their fatigue behavior in a project supported by DFG at Technische Universität Berlin, Germany.

penther@tu-berlin.deDaniela Penther et al., Res. Rev. J Mat. Sci. 2017, 5:7

DOI: 10.4172/2321-6212-C1-011