Page 59

Journal of Material Sciences

ISSN: 2321-6212

I n t e r n a t i o n a l C o n f e r e n c e o n

Metal, Mining and

Magnetic Materials

N o v e m b e r 0 1 - 0 2 , 2 0 1 8

P a r i s , F r a n c e

Metal and Magnetism 2018

Effect of ruthenium additions on the corrosion and mechanical

properties of the weld metal of 316L austenitic and LDX 2101

duplex stainless steels

Bridget N Zuma

1, 2

and J W van der Merwe

1,2,3

1

University of the Witwatersrand Johannesburg, South Africa

2

DST-NRF Centre of Excellence in Strong Materials-University of the Witwatersrand Johannesburg,

South Africa

3

African Materials Science and Engineering Network-University of the Witwatersrand

Johannesburg, South Africa

A

ustenitic stainless steels (ASSs) and duplex stainless steels (DSSs) are widely used in high performance pressure vessels,

nuclear, chemical, process and medical industry due to their very good corrosion resistance and superior mechanical

properties. Welding is a common technique used to join 316L ASS or LDX 2101. 316L is a molybdenum bearing ASS, while

LDX 2101 is a duplex stainless steel that was patented by Outokumpu in 2013. This work validated the potential benefit that

Ru additions would have on the corrosion resistance of the weld metal based on microstructural and mechanical properties.

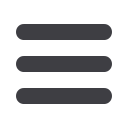

The microstructures of all 316L gas tungsten arc welding (GTAW) button samples in Figure 1 exhibited γ-austenite phases with

δ-ferrite at the dendritic boundaries. The ferrite-austenite (FA) solidification mode suggested that an incomplete solid-state

transformation had occurred due to the melting of the 316L in water cooled conical shaped copper mould. The hardness results

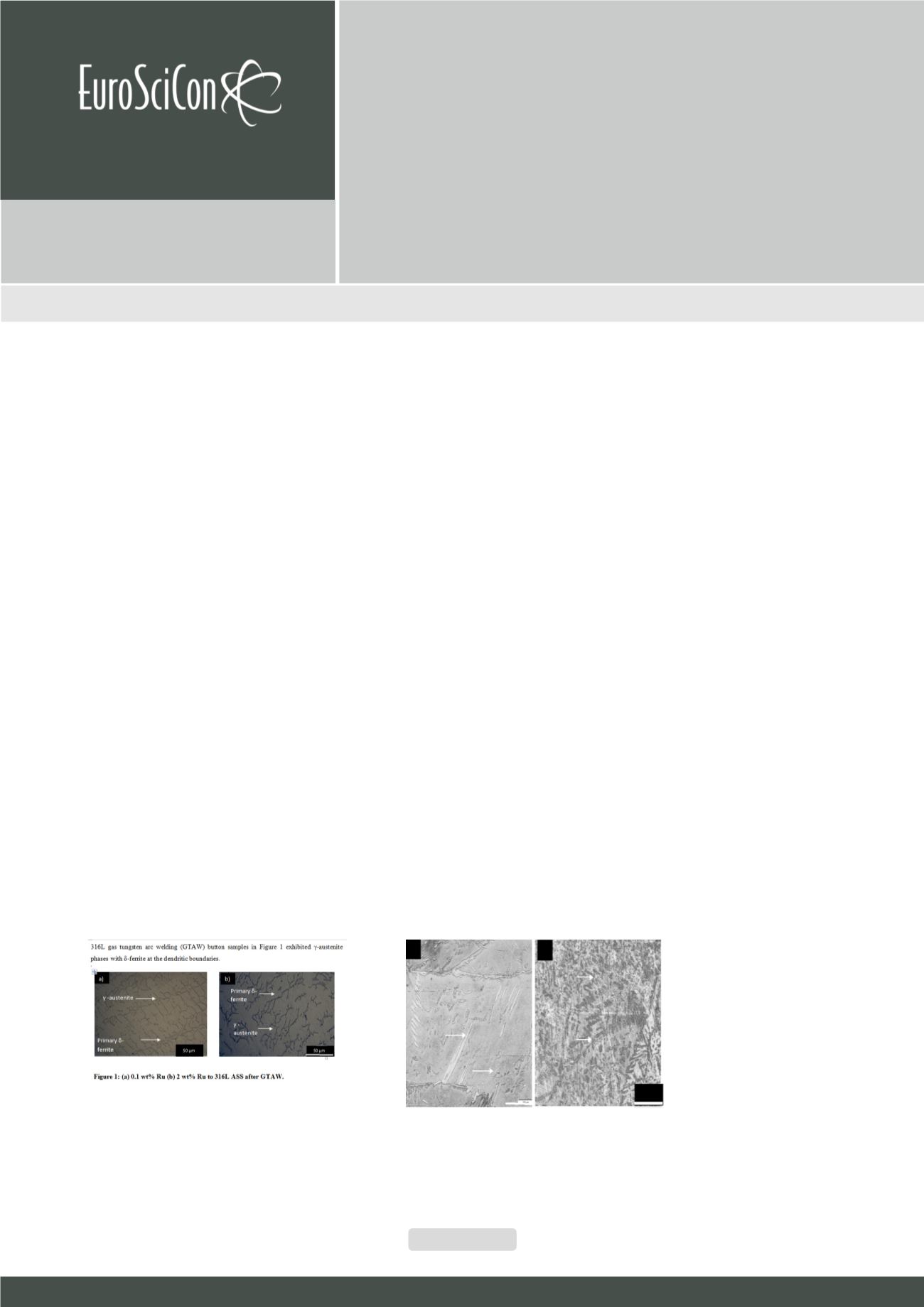

revealed that 316L ASS (Figure 1) and LDX 2101 (Figure 2 had an increase in hardness as Ru additions were increased due to

grain refining nature of Ru). The potentiodynamic polarization test indicated that as Ru addition increased there was an increase

in corrosion resistance for both 316L and LDX 2101. Overall, it was concluded that the addition of Ru exhibited no detrimental

effect of the solid state transformation but rather strengthens the alloy as Ru increases. Ruthenium additions in the stainless

steels not only improve the weld metal mechanical properties but can improve the corrosion resistance of the weld metal.

bridgetzuma@gmail.comJ Mat. Sci. 2018, Volume:6

DOI: 10.4172/2321-6212-C7-033

Figure 1:

(a) 0.1 wt % Ru (b) 2 wt % Ru to 316L ASS after GTAW.

Bulkyδ-ferritephasesextendingtothindendritearmswereob-

served at 0.1 wt % Ru (Figure 1 a) while a skeletal δ-ferrite mi-

crostructure (Figure 1 b) was observed with 2 wt % Ru addition

Figure 2:

(a) 0.1 wt % Ru (b) 2 wt % Ru to LDX 2101 ASS after GTAW