Page 107

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

Microstructural, mineralogical and chemical characterization of a new 3D stratified Si-Ca-P porous scaffolds

obtained by sol-gel and polymer replica method

De Aza P.N

4

,

Ros-Tárraga P

1

, Murciano A,

2

Mazón P

2

and

Gehrke, S.A

3

1

UCAM-Universidad Católica San Antonio de Murcia, Spain

2

Universidad Miguel Hernández, Spain

3

Biotecnos Research Center, Brasil

4

Universidad Miguel Hernández Avda, Spain

S

tatement of the Problem: Tissue engineering is a science which studies different ways to achieve the regeneration of diseased

tissues. To get it, this field uses scaffolds or porous extracellular 3D matrices, which allow cell migration, vascularization and

nutrient diffusion. These matrices need to have the appropriate physical and biological properties such as pore size and structure,

surface topography, chemical composition, mechanical strength and degradation rate. These characteristics are capable to induce

optimal osteogenesis throughout the scaffolds. For this reason, and because they exhibit an appropriate bioactivity, ceramics are

excellent candidates for developing these 3D scaffolds, avoiding the process of stress shielding. The aim of this research was to develop

and characterize a novel stratified porous scaffold for future uses in bone tissue engineering. Methodology &Theoretical Orientation:

In this study, a calcium silicophosphate porous scaffold, with nominal composition 29.32 wt% SiO

2

– 67.8 wt% CaO – 2.88 wt%

P

2

O

5

, was produced using the sol-gel and polymer replication methods. Polyurethane sponges were used as templates which were

impregnated with a homogeneous sol solution and sintered at 950ºC and 1400ºC during 8 hours.The characteristics of the 3D stratified

porous scaffolds were investigated by Scanning Electron Microscopy, X-Ray Diffraction, Fourier Transform Infrared Spectrometry,

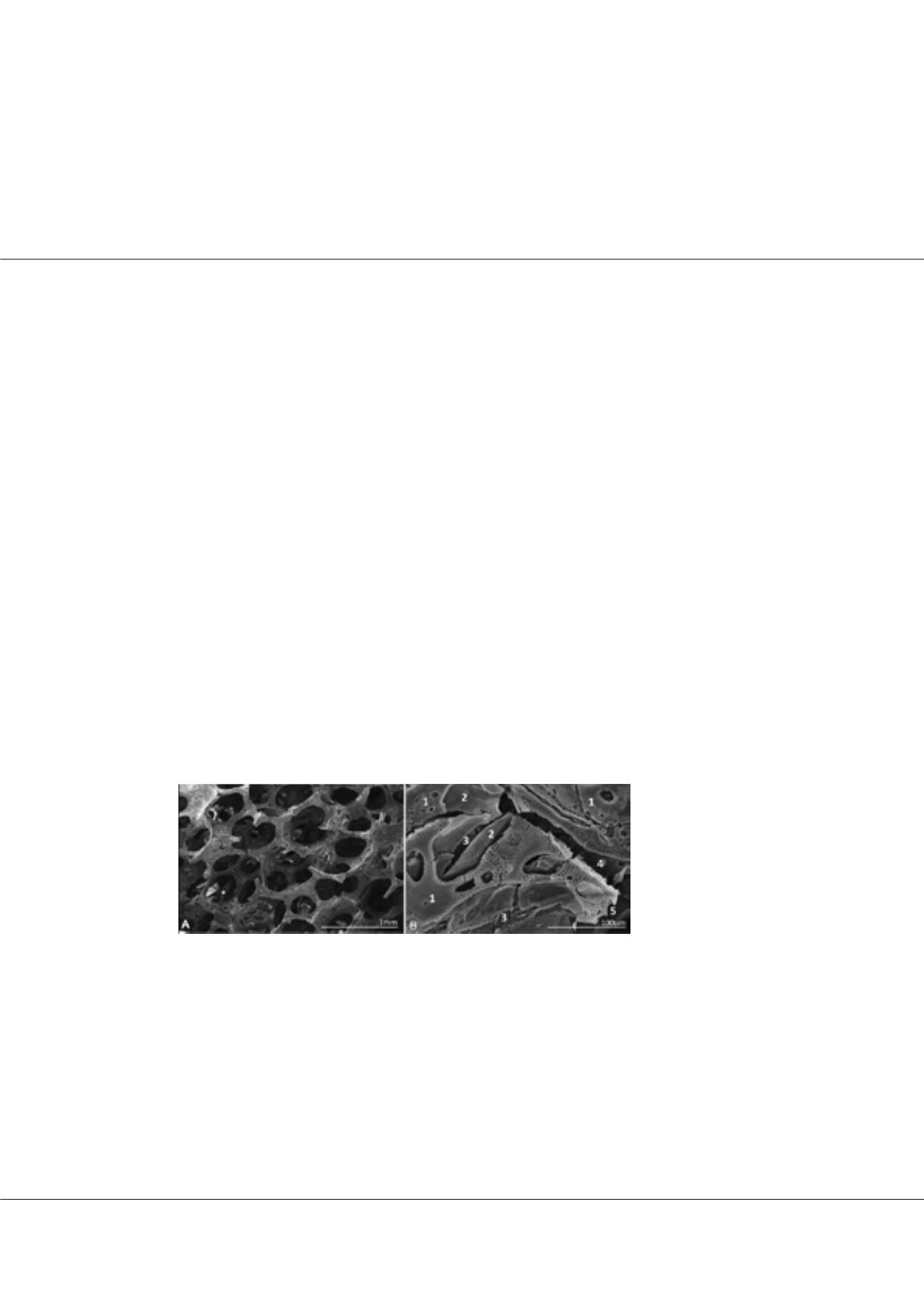

Diametric Compression of Discs Test and Hg porosimetry techniques. Findings: The result showed highly porous stratified calcium

silicophosphate scaffolds with micro and macropores interconnected. Also, the material has a diametrical strength dependent on

the number of layers of the stratified scaffolds and the sintering temperature. Conclusion & Significance: A new methodology has

been developed to obtain a stratified porous 3D ceramic at different temperatures, whose microstructural study has shown a highly

interconnected porosity, with an average pore size between 375-400 µm and a Ca/P ratio of 13.09. For this reason, this methodology

will allow us to create new customized materials according to the needs of each situation. We will be able to create materials with

a high resistant core and high bioactivity coverings or vice versa, depending on the place where you would place the bone implant.

Biography

Piedad N de Aza received her doctoral degree in Chemistry-Ceramic 1995. She did a postdoctoral stage at the IRC in Biomaterials at the Queen Mary College,

University of London (U.K.) working on in vitro and in vivo behavior of bioceramics. At this moment, she is the Chair of the Materials Science, Optic and Electronic

Technology Department, Professor of Materials Science and Metallurgical Engineering and Researcher at the Bioengineering Institute at the Miguel Hernandez

de Elche University..

piedad@umh.esDe Aza P.N et al., Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-006

Fig1

:

SEM micrographs of the

3D-1400 ceramics with a) 10 and

c) 12 immersions in sol-solution

(numbers are the latest five

layers)