Page 34

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

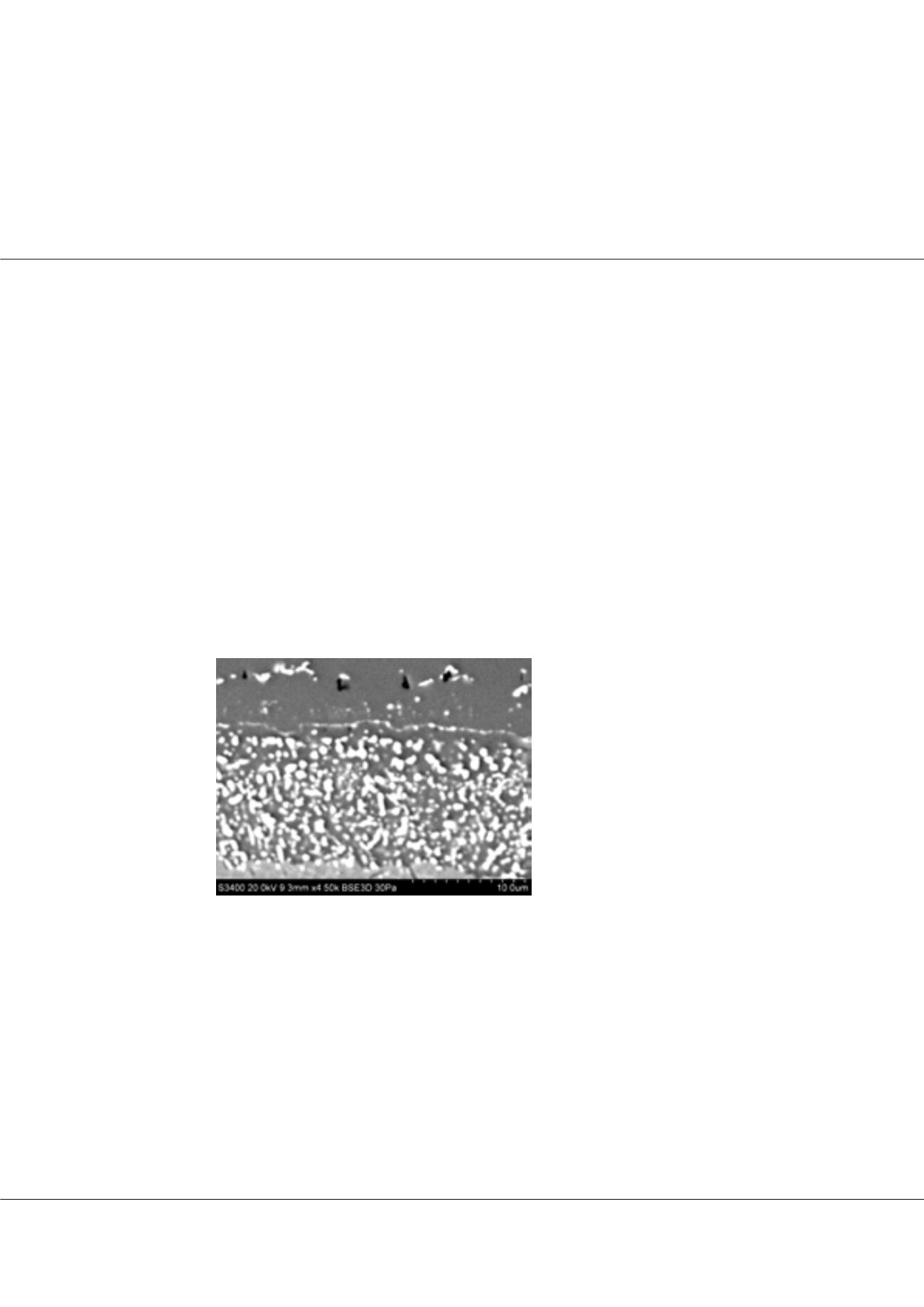

Hafnium and palladium modified aluminide coatings

Jolanta Romanowska

and

Maryana Zagula-Yavorska

Rzeszów University of Technology, Poland

H

afnium or palladium modification of NiAl phase increases the oxidation resistance of aluminide coatings deposited on turbine

blades in a hot section of jet engines. Small hafnium or palladium addition to aluminide coatings decreases the oxidation rate of

turbine blades made of nickel superalloys. Small content of hafnium (0.1-1.0 % wt) improves high temperature mechanical properties

of aluminized nickel based superalloys. Palladium modification increased the outer zone hardness. It is due to the presence of the σ

and µ phases. The palladium or hafnium modified aluminide coatings have better oxidation resistance than the non-modified ones.

The use of ‘co-doping’ has recently been emphasized as a strategy for optimizing the oxidation resistance of superalloys, conventional

alloys and coatings The comparison of structures of hafnium and palladium modified aluminide coatings deposited on pure nickel

and CMSX

4

nickel superalloy is presented. Aluminide layers were deposited by the Chemical vapor deposition (CVD) method.

Hafnium was deposited simultaneously with aluminum. Aluminum was deposited from the AlCl

3

and hafnium from the HfCl

3

gas

phases. Palladiumwas deposited by the electrodeposition method. The obtained coatings were examined using an optical microscope,

a scanning electron microscope and an XRD phase analyzer. Both coatings consist of two layers; an outer, comprising the ß-NiAl

phase and the interdiffusion one. The interdiffusion layer on pure nickel consists of the γ’-Ni

3

Al phase, whereas on the CMSX

4

– of the

ß-NiAl phase. Small inclusions of Pd and Hf rich phases were found at the border of the layers on nickel, whereas inclusion containing

Pd, Hf and refractory elements were observed in the interdiffusion zone on the CMSX

4

superalloy. The research has been supported

by the National Science Centre, Poland Grant No. 2015/19/B/ST8/01645.

Biography

Jolanta Romanowska has completed her PhD from AGH University of Science and Technology, Cracow, Poland and DSC from the Silesian University of

Technology, Poland. She is the professor at the Rzeszów University of Technology, Poland. She has published more than 50 papers in reputed journals. She has

her expertise in thermodynamics of alloys and protective coatings. She elaborated the model of predicting thermodynamic properties of ternary alloys on the basis

of thermodynamic properties of binary alloys.

jroman@prz.edu.plJolanta Romanowska et al., Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-005

Fig.1:

Cross-section microstructure of aluminide

coating obtained by CVD method on pure nickel

(a), and CMSX4 nickel superalloy (b)