Page 85

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

Microstructure development affected by electrode geometry during resistance spot welding

Peng-Sheng Wei

National Sun Yat-Sen University, Taiwan

R

esistance spot welding is an important technique often used in joining thin workpieces in different manufacturing, aerospace,

aeronautics and automobile industries. This presentation theoretically and quantitatively investigates and interprets processes

by realistically accounting for transient magneto-fluid mechanics, heat and species transport, and temperature-dependent bulk

resistance in workpiece, and film and constriction resistances at contact interfaces. Since temperature gradient and solidification rate

are found, the computed morphological parameter, namely, the ratio between temperature gradient and solidification rate, shows

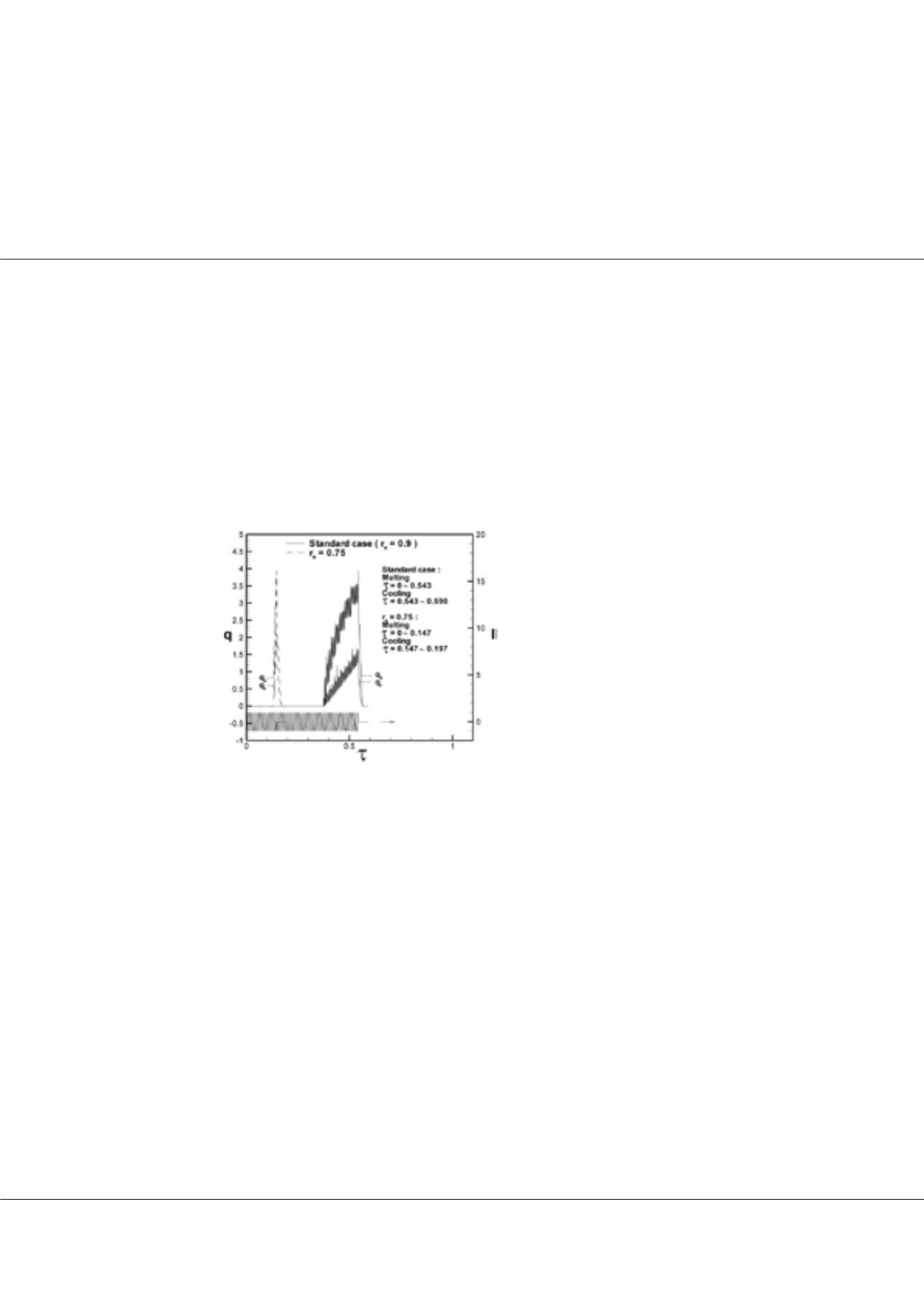

that electrode geometry can be designed to control microstructures of the weld nugget. Figures 1(a) and (b) show that solidification

rate decreases whereas heat flux increases as electrode face radius decrease, respectively. A decrease in electrode face radius therefore

increases the morphology parameter, leading to columnar dendrites, whereas cooling rates can be decreased or increased.

Biography

Dr. Peng-Sheng Wei received Ph.D. in Mechanical Engineering Department at University of California, Davis, in 1984. He has been a prof essor in the Department

of Mechanical and Electro-Mechanical Engineering of National Sun Yat-Sen University, Kaohsiung, Taiwan, since 1989. Dr. Wei has contributed to advancing

the understanding of and to the applications of electron and laser beam, plasma, and resistance welding through theoretical analyses coupled with verification

experiments. Investigations also include studies of their thermal and fluid flow processes, and formations of the defects such as humping, rippling, spiking and

porosity. Dr. Wei has published more than 80 journal papers, given keynote or invited speeches in international conferences more than 90 times. He is a Fellow of

AWS (2007), and a Fellow of ASME (2000). He also received the Outstanding Research Achievement Awards from both the National Science Council (2004), and

NSYSU (1991, 2001, 2004), the Outstanding Scholar Research Project Winner Award from National Science Council (2008), the Adams Memorial Membership

Award from AWS (2008), the Warren F. Savage Memorial Award from AWS (2012), and the William Irrgang Memorial Award from AWS (2014). He has been the

Xi- Wan Chair Professor of NSYSU since 2009, and Invited Distinguished Professor in the Beijing University of Technology, China, during 2015-2017.

pswei@mail.nsysu.edu.twPeng-Sheng Wei, Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-005

Fig.1

(a) Growth and recession rates of nugget, and (b) heat

flux or temperature gradient in radial and axial directions for

different electrode face radii.