Page 59

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

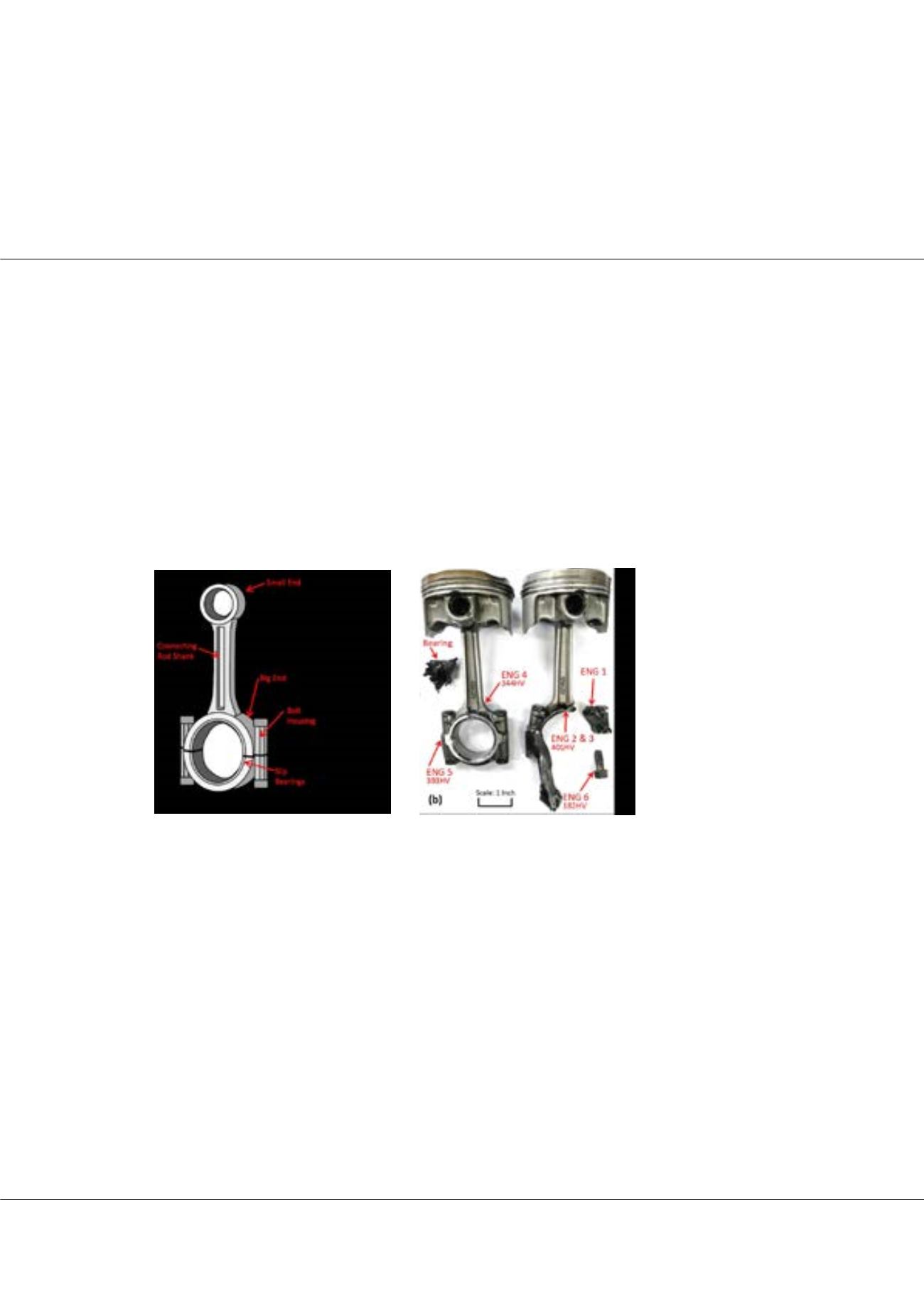

Fatigue analysis of a failed connecting rod in race car engine

K. Bari

1

, A. Rolfe

1

, A. Christofi

1

, C. Mazzuca

1

and

K.V. Sudhakar

2

1

University of Derby, United Kingdom

2

Montana Tech of the University of Montana, USA

I

n the present work, a failed connecting rod from a motorcycle engine was investigated for the root cause of and possible mechanisms

leading to its premature failure. In addition to finding the root cause, the expectation from this study was to possibly improve the

existing designs or practices to avoid similar failures in future. These results were validated using a finite element analysis (FEA)

simulation. A Scanning Electron Microscope was used for investigating the mechanisms of fracture modes, optical microscopy for

studying the microstructures and visual inspection were primarily utilized to determine the root cause of the failure. In conclusion,

it was determined that the root cause for the premature failure of the connecting rod was the presence of scale build-up inclusions,

which led to micro cracking during fatigue loading of the component. It is most likely that the connecting rod failed on the end of

exhaust stroke, due to the tensile force being at its highest, when the piston reaches TDC. This is due to the inertia of the piston, pin,

and upper end of the connection rod moving upwards while there are no compressive forces to take them under consideration.

Biography

Dr. Klaudio Bari is a senior Lecturer at University of Derby. He has passion for fatigue in engine component, in particular race car, that endure stress, heat and

corrosion environment at the same time. Stress crack corrosion is a complex subject and can be only understood after comprehensive analysis in term of using

scanning electron microscope and particular mode (EBSD). In general, visual analysis can be helpful sometime, but often is misleading the fact and lead the

investigator to wrong conclusion. Conservative approach in failure analysis is definitely his strong point in Engineering.

k.bari@derby.ac.ukK. Bari et al., Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-005

Figure1:

(a) Diagram of an assembled

connecting rod, rod cap, bolts and

slip bearing with key features and

components annotated in red; (b)

The intact and failed connecting rod

and piston assemblies, left and right

consecutively, are shown with the

failure.