Page 61

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

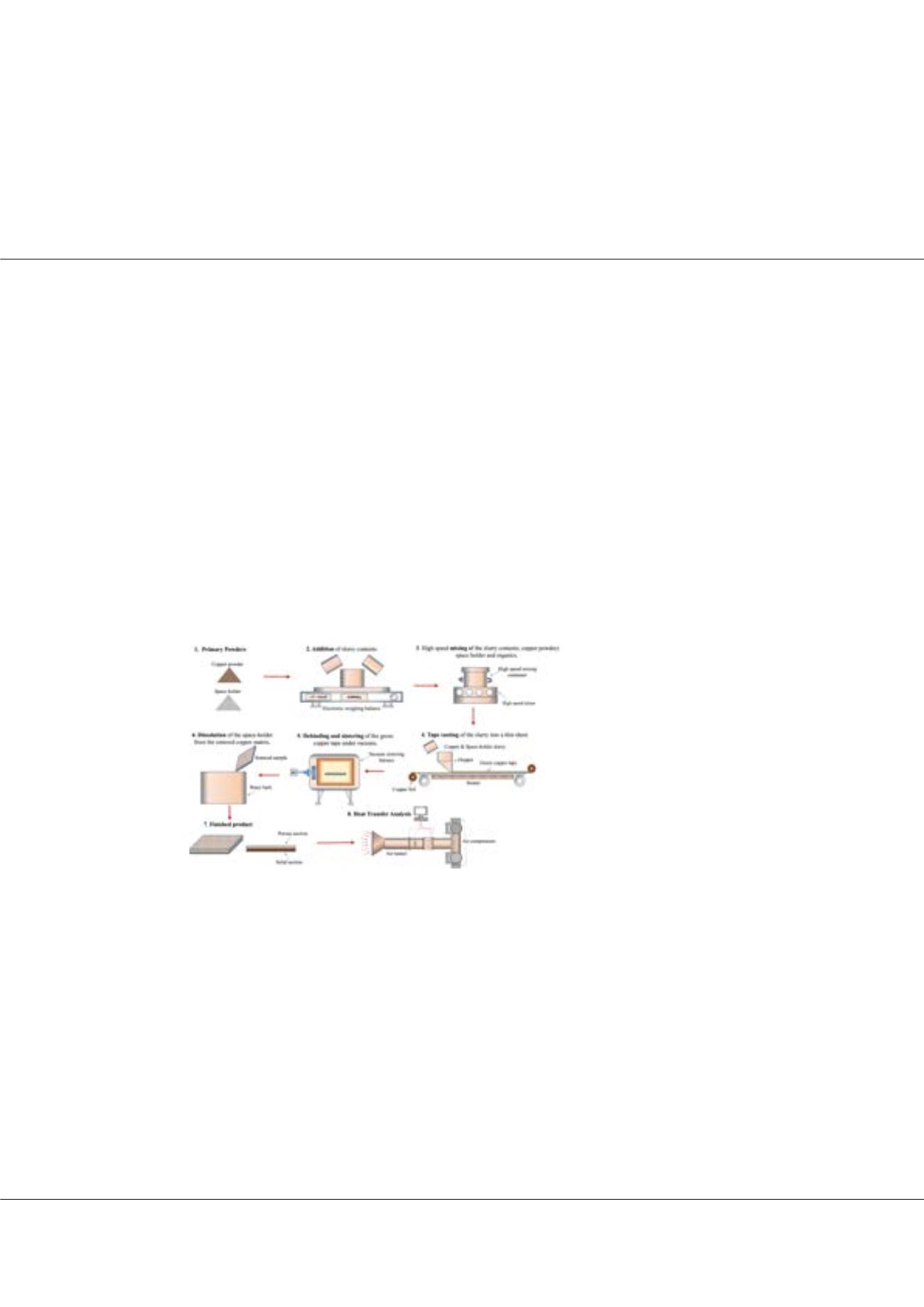

Heat transfer performance of double-layer porous copper produced by tape casting with lost carbonate sintering

Mosalagae Mosalagae

1

, Ahmed AAG. Al-Rubaiy

2

, Russell Goodall

1

and

Robert Woolley

2

1

Department of Materials Science and Engineering, University of Sheffield, UK

2

Department of Mechanical Engineering, University of Sheffield, UK

P

orous copper tapes with high surface area to thickness ratio are attractive for thermal management in portable electronics where

good heat transfer performance is required. In this study, the porous sheets of thickness down to

1350µm

were investigated for

heat transfer performance. The porous copper samples were produced by a novel process combining lost carbonate sintering (LCS)

and tape casting. This process allows the flexibility to produce copper double-layer structure consisting of a porous section with a

wide range of porosities on a dense substrate. Here double-layer structures consisting of a porous layer of porosities ranging from

30-

70%

were investigated. Their suitability for heat sink applications were investigated with simple assessments of the thermal properties

under forced convection using air as a coolant. Through experiments, the heat transfer performance of the thin porous tapes was

systematically studied under two different heating systems; a cylindrical and flat heating systems. The heat generated within the

heating systems was controlled by AC/DC power supply. Also the flow rate of air passing through the samples was varied between the

ranges of 0 – 0.5 kg/s. T- type thermometers and an Infrared thermography sensor were installed in the system to track in and out

and surface temperatures of the system. This allowed behavior of heat dissipation by porous copper tapes to be effectively studied. The

initial experimental results showed that, from the thermal viewpoint, the porous copper heat sinks investigated here have an excellent

heat transfer performance. The outcome of this study is fully discussed in the presentation.

Biography

Mosalagae Mosalagae is a professional, highly motivated and dedicated materials science and engineering researcher. His main interest is on development of

porous metals for heat transfer applications by powder metallurgical processes. He developed a process which combines lost carbonate sintering (Zhao et al, 2004)

and tape casting to process copper powder into thin sheet of porous copper, and further developed a heat transfer rig to investigate the porous heat sinks produced

by simple assessment of thermal properties. In this rig, porous metals are tested under a forced convection using air as a coolant.

mmosalagae1@sheffield.ac.ukMosalagae Mosalagae et al., Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-005

Figure1

Schematic diagram showing

processing and heat transfer analysis of

porous copper samples