Page 53

conferenceseries

.com

Volume 6

Research & Reviews: Journal of Material Sciences

MatSciEngg 2018

October 15-17, 2018

October 15-17, 2018 Helsinki, Finland

31

st

Materials Science and Engineering

Conference: Advancement & Innovations

Regenerated cellulose fibers spun from 1-ethyl-3-methylimidazolium diethyl phosphate/dimethyl

sulfoxide co-solvent systems

Jiaping Zhang, Keita Tominaga and Yasuo Gotoh

Shinshu University, Japan

I

onic Liquids (ILs) after reported by Swatloski, et al. in 2002 have

drawn much attention as solvents for cellulose. However, the

viscosity of cellulose/ILs solutions is relatively high, which requires

longer solubilization time leading to high cost and negative effect

on spinning. Some works about the addition of co-solvents into

cellulose/ILs solution systems have been reported aiming to reduce

the viscosity of the solutions. The addition of highly polar aprotic

solvents such as dimethylformamide and Dimethyl Sulfoxide

(DMSO) to ILs was found to possibly decrease the viscosity of

cellulose solutions. Moreover, some reports showed that co-

solvents could accelerate the dissolution of cellulose, which was

particularly favorable for cellulose processing. However, to the

best of our knowledge, there are few works concentrating on the

final properties of cellulose regenerated cellulose fibers spun from ILs/co-solvents systems. Herein, in this study, regenerated

cellulose fibers were prepared from co-solvent system consisting of a kind of imidazolium ILs, 1-Ethyl-3-Methylimidazolium

Diethyl Phosphate (EMIMDEP) and DMSO via dry-jet wet spinning. The spinnability of spinning dopes, mechanical

properties, structures and fibrillation behaviors of the regenerated fibers were investigated by comparing with pure EMIMDEP

system. The results showed that the spinnability determined by the maximum winding speed reduced to less than half of that

for cellulose/EMIMDEP solution after addition of 30 wt% DMSO. This may be derived from reduction of elongation viscosity,

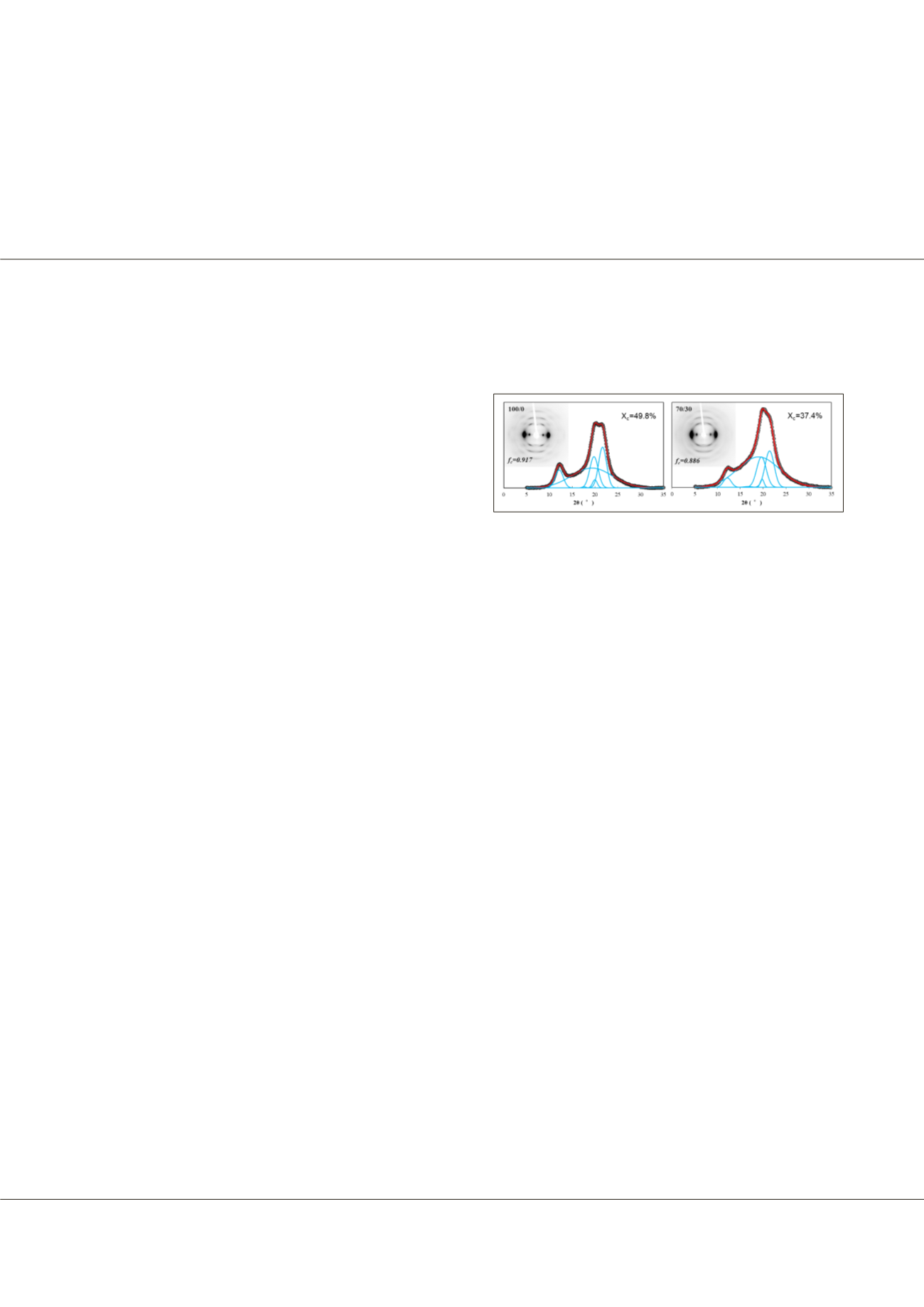

which leads to decrease in strength of spinning line under elongation flow. Moreover, regenerated cellulose fibers spun from

EMIMDEP/DMSO 70/30 (wt/wt) showed lower tensile strength and Young’s modulus, but superior fibrillation resistance. This

was thought to be related to its low crystalline orientation and low degree of crystallinity.

Biography

Jiaping Zhang is a PhD student in Shinshu University, Japan. She studies mainly about the preparation of high performance regenerated cellulose fibers and ultrafine

regenerated cellulose nonwoven fabrics in the Department of Materials Science and Engineering. She belongs to global leader program for fiber renaissance, which

aims to cultivate young researchers with broader perspective, leadership and management skills.

17st306e@shinshu-u.ac.jpJiaping Zhang et al., Res. Rev. J Mat. Sci. 2018, Volume 6

DOI: 10.4172/2321-6212-C5-027

Figure-1: WAXD profiles with de-convoluted peaks

for powdered regenerated cellulose fibers spun from

EMIMDEP/DMSO solutions (100/0 (left image) and

70/30 wt/wt (right image)). X-ray fiber photographs of

aligned fibers were also put in the figures.