Page 33

conferenceseries

.com

Volume 6

Research & Reviews: Journal of Material Sciences

MatSciEngg 2018

October 15-17, 2018

October 15-17, 2018 Helsinki, Finland

31

st

Materials Science and Engineering

Conference: Advancement & Innovations

Development of high strength- high porosity Si

3

N

4

bodies via a modified gel-casting process

Amir Parsi, Farhad Golestanifard*, Seyyed Mohammed Mirkazemi

Iran University of Science and Technology, Iran

P

orous Si

3

N

4

bodies are of interest in various applications including bio and aerospace.

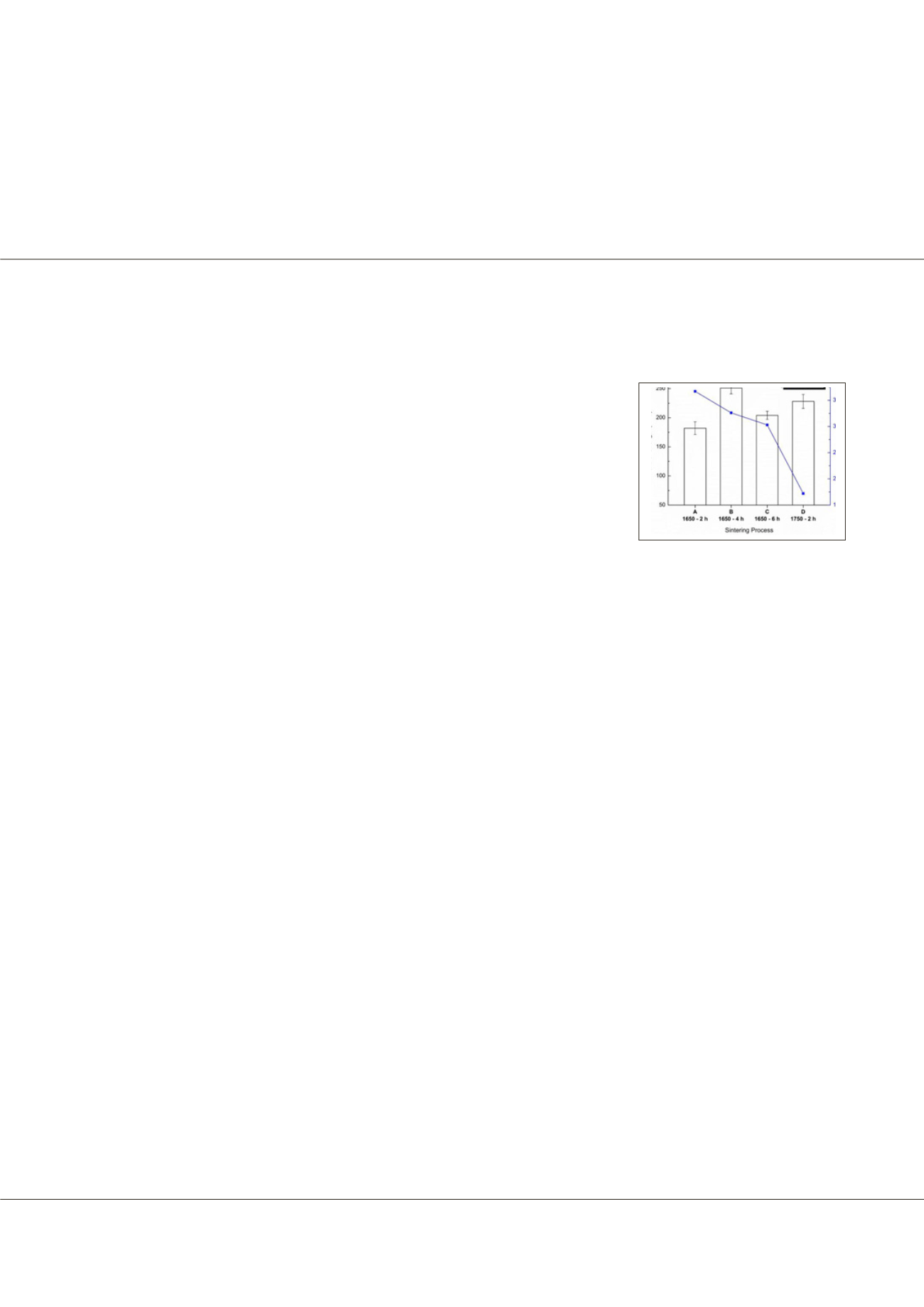

Silicon nitride bodies were prepared with porosity and flexural strength of about 38%

and near 180 MPa, respectively. The processing was via gel-casting method employing

acrylamide (AM) and N,N'−methylene bisacrylamide (MBAM) for primary slurry,

followed by coke bed sintering. The concentrations of APS and TEMED as initiator and

catalyst, the sintering time and temperature were studied and optimized. Phase evolution

and microstructure observation, as well as flexural strength and porosity of porous Si

3

N

4

bodies, were investigated. It was found above, sintering process at 1650 °C with prolonged

time had a significant effect on strength in a way that bodies with 33% porosity could

experience of 250 MPa. Development of interlocking microstructure of fine β-Si3N4

grains was found to be the key factor for increase of strength. Controlling the primary slurry components was also vital for

maintaining the high strength. The results were explained with emphasis on potential applications.

Biography

Amir Parsi received the

B.Sc.degree in Materials Science and Engineering from Sharif University of Technology (SUT), Tehran, Iran, in 2012, and the

M.Sc.

degree in Ceramic Engineering from Iran University of Science and Technology (IUST), Tehran, Iran, in 2015. Since then, he has been working under supervision

of Prof. Golestanifard in the Refractory and Ceramic Synthesis Lab in the IUST. He is not carrying on research on synthesis ceramic powders but also being the lab

manager. He has won the Best Poster Award from 10th Congress of the Iranian Ceramic Society (ICerS) & First International Conference on Advanced Ceramics

for a paper entitled "Rheological Properties of Silicon Nitride Slurries for Gelcasting". In recent years, he has focused on preparing porous Silicon Nitride ceramic

bodies with high strength with the intention of utilizing in bio applications.

amr.ac68@gmail.comAmir Parsi et al., Res. Rev. J Mat. Sci. 2018, Volume 6

DOI: 10.4172/2321-6212-C5-026