Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

Page 23

conference

series

.com

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

Leszek A Dobrzanski, Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-004

The skeletonmicroporousmaterials with coatings inside the pores formedical and dental applications

A

significant and costly problem of the modern medicine is the necessity to replace or supplement organs or tissues

to prevent the biological and social degradation of patients and to restore their living functions, resulting from a growing

number of cases of organ or tissue loss or damage in the human population due to post-injury or post- resection losses as

well as those originating from the operative treatment of cancerous tumours or inflammation processes and as a result of

the work, traffic and sports accidents. The own works covered by this article form part of completely original and pioneer

research over the development of original author’s concepts concerning the development of original hybrid clinical

prosthetics and implantation techniques in the area of medicine and regenerative dentistry and tissue engineering

methods allowing for the natural growth of living tissues into microporous parts of implanted medical devices. An

engineering manifestation of such concepts is the creation of a new generation of original hybrid microporous high-strength

engineering materials ensuring the development of original hybrid constructions of a new generation of personalised

implant-scaffolds and tissue scaffolds. The most important is to develop an original hybrid technology of fabrication

of a new generation of custom implant- scaffolds and tissue scaffolds using skeleton titanium or Ti

6

AlV

4

alloy microporous

materials manufactured by Selective Laser Sintering. They exhibit porosity and the related mechanical properties dependent

on the manufacturing conditions, including mainly laser power, laser beam diameter and distance between laser beams and

distance between laser remelting paths. In order to ensure conditions for the nesting and proliferation of living tissues in the

micropores of the created porous microskeletons, tests were performed of the deposition of the internal surface of micropores

with TiO

2

and Al

2

O

3

layers by ALD technology supporting the growth of living tissues in a microporous bonding zone with

scaffolds or implant-scaffolds created from engineering materials.

Biography

Prof. LeszekAdamDobrzanski is a Full Professor of Materials Engineering, Manufacturing Engineering , Nanotechnology, Medical and Dental Engineering in the Silesian

University of Technology in Gliwice, Poland and a Supervisory Board Chairman, Project Manager and Principal Investigator in the Medical and Dental Engineering

Centre for Research, Design and Production ASKLEPIOS Ltd in Gliwice, Poland. He is a Doctor Honoris Causa of the Universities in Bulgaria, Hungary and Ukraine. He

is a Fellow of the Materials Science Committee of the Polish Academy of Sciences PAS and the President of the Metallic Materials Section of this Committee. He is a

Vice President and a Fellow of the Academy of Engineers in Poland. He is a foreign Fellow of the Ukrainian Academy of Engineering Sciences and the Slovak Academy

of Engineering Sciences. He is the President of the World Academy of Materials and Manufacturing Engineering, and a President of the International Association of Com-

putational Materials Science and Surface Engineering. He is the Editor-in-Chief of the Journal of Achievements in Materials and Manufacturing Engineering, Archives of

Materials Science and Engineering and Open Access Library.

leszek.adam@gmail.comLeszek A Dobrzanski

World Academy of Materials and Manufacturing Engineering, WAMME, Poland

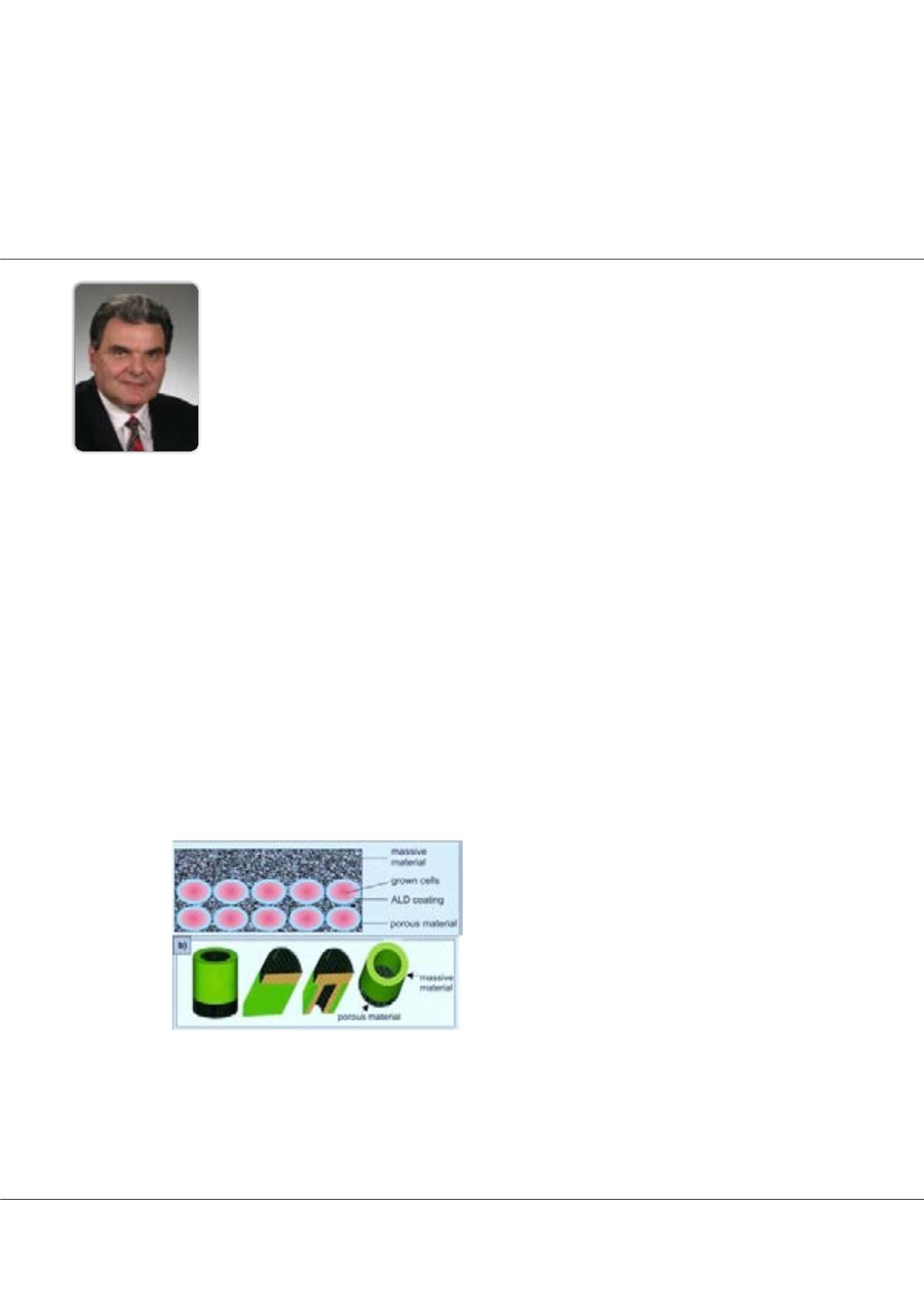

Figure 1:

The rigid biological-engineering material which may

represent a microporous part of original implant-scaffolds

with a microporous skeleton and deposited coatings by the

atomic layer deposition method inside the pores supporting

the growth and proliferation of living cells.