Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

Page 68

conference

series

.com

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

Mosongo Moukwa, Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-004

Influence of non-Newtonian behavior of polymers on their processing characteristics

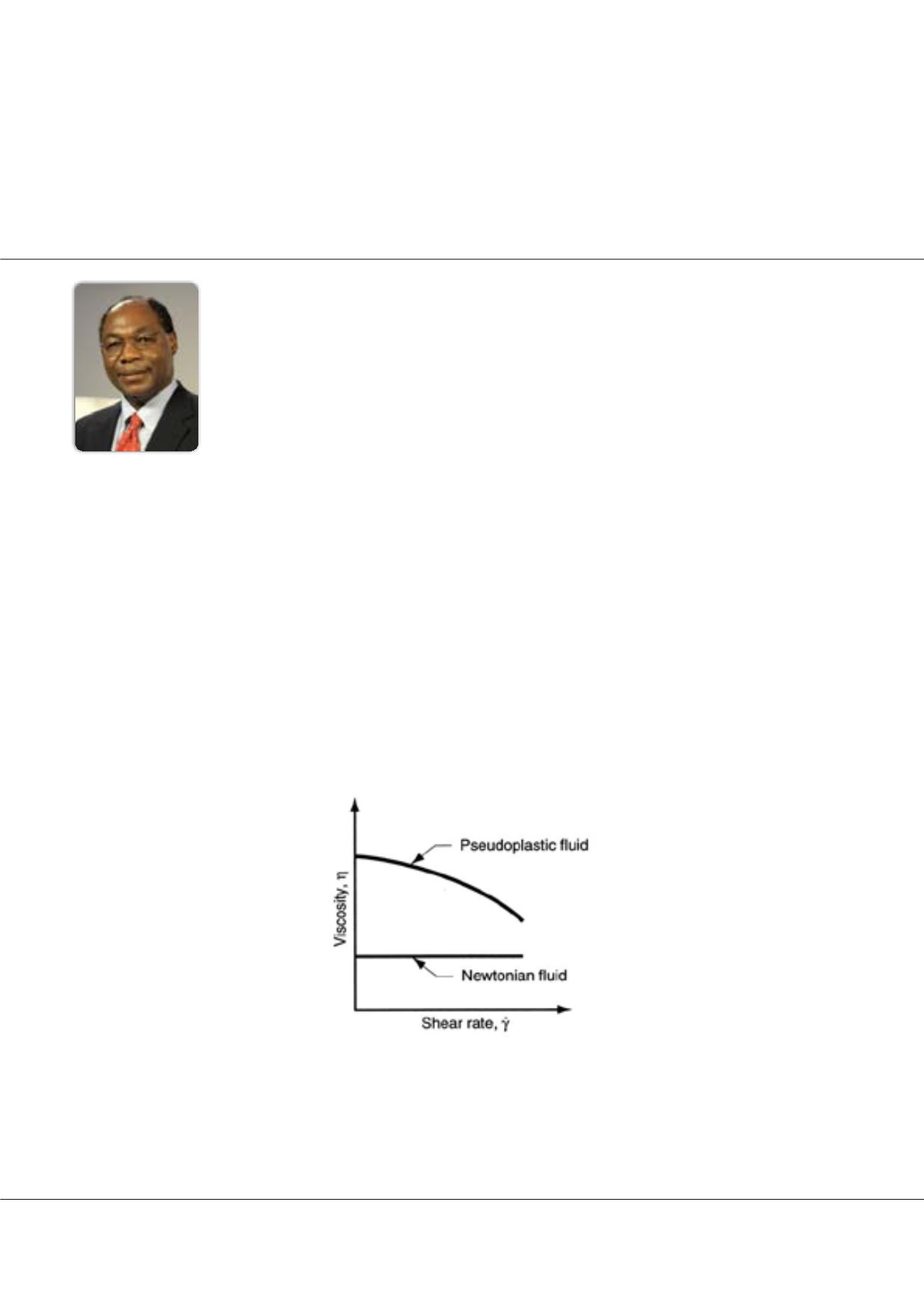

D

uring the manufacture of polymeric (or plastic) materials, polymers are subjected to flow. The way these liquids react

is determined by the shapes, or configurations that the molecules adopt. Polymer molecules behave like springs, and

become stretched by the flow, giving rise to the strongly elastic behavior of polymeric fluids. The study of the dynamics of

polymer molecules is very important for the understanding of flow of polymeric fluids. The unique properties of polymers are

often not apparent until they are encountered by chemical engineers on the job. The unique qualities of polymers most evident

in their processing, the fabrication of bulk polymer (resin) into a finished article, which typically requires an entirely different

equipment than that required to process conventional liquids. What makes polymeric materials interesting in this context is

the fact that their time constants for flow are of the same order of magnitude as their processing times for extrusion, injection

molding and blow molding. In very short processing times, the polymer may behave as a solid, while in long processing times

the material may behave as a fluid. This dual nature (fluid-solid) is referred to as viscoelastic behavior. Elastic stresses in

polymeric and other complex fluids can give rise to strange flow behavior not seen in Newtonian fluids. This can for example,

produce undesirable instabilities in industrial processes. Interfacial instability in co-extrusion leads to defects consisting of

highly irregular or sometimes regular waviness which appears in coextruded structures at the polymer/polymer interface.

The effect is to significantly reduce the optical quality of coextruded film. It is an internal defect, which distinguishes it from

sharkskin, which is a surface defect. In this presentation we will discuss how the non-Newtonian behavior affects processing

of polymers, using examples.

Biography

Mosongo Moukwa is a senior level management professional and entrepreneur recognized for his achievements to helping companies improve their profitability by

commercializing new technologies and developing new markets. His was Vice President of Global Technology at Johnson Polymer, WI, now part of BASF, Vice President

of Global Technology at Reichhold, NC, and Vice President of Technology at Asian Paints, India. He is now Director of Technology at PolyOne Designed Structures and

Solution LLC, based in Saint Louis, MO. He holds a PhD from the Universite de Sherbrooke, Quebec, Canada and was a NSERC postdoctoral fellow at Northwestern

University, IL.

mmoukwa@aol.comMosongo Moukwa

Spartech LLC (formerly PolyOne DSS), USA