Page 102

conferenceseries

.com

Volume 6

Research & Reviews: Journal of Material Sciences

ISSN: 2321-6212

Advanced Materials 2018

September 04-06, 2018

September 04-06, 2018 | Zürich, Switzerland

21

st

International Conference on

Advanced Materials & Nanotechnology

Horizontal twin roll casting of aluminum alloy A7075

Yuta Kashitani

1

, Shinichi Nishida

1

, Junshi Ichikawa

1

, Kentaro Tsunoda

1

, Yuto, Horigome

1

, Naoki Ikeda

1

, Daichi Uematsu

1

, Makoto Hagiwara

1

, Hideto

Harada

1

and

Toshio Haga

2

1

Gunma University, Japan

2

Osaka Institute of Technology, Japan

T

his paper describes a horizontal type twin roll strip casting process for producing aluminum alloy strip of A7075. Twin roll

casting process is able to produce a strip from molten metal directly. Thus this process has a possibility to reduce total cost of

sheet making comparing to conventional rolling process. Strip casting process has some disadvantages. Casting speed depends on

the material properties. It is difficult to determine the casting conditions. Aluminum alloy A7075 has high tensile strength, and it is

known as a material for aerospace application. The sheet is manufactured in small quantities comparing to the other sheet aluminum

alloy. Because A7075 alloy sheet is generally needed to a number of rolling and annealing process after hot extrusion. It is supposed

that the demand of high tensile strength aluminum sheet such as A7075 is going to increase for weight saving of structural material.

In this study, the effect of pouring temperature on the strip was investigated. Castability, surface conditions microstructure and strip

thickness were estimated. It was possible to produce strip at any pouring temperature by horizontal twin roll strip casting process.

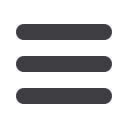

Each surfaces of produced strip were transcribed form the roll surface, and the surfaces had a metallic luster. Minor cracks occurred

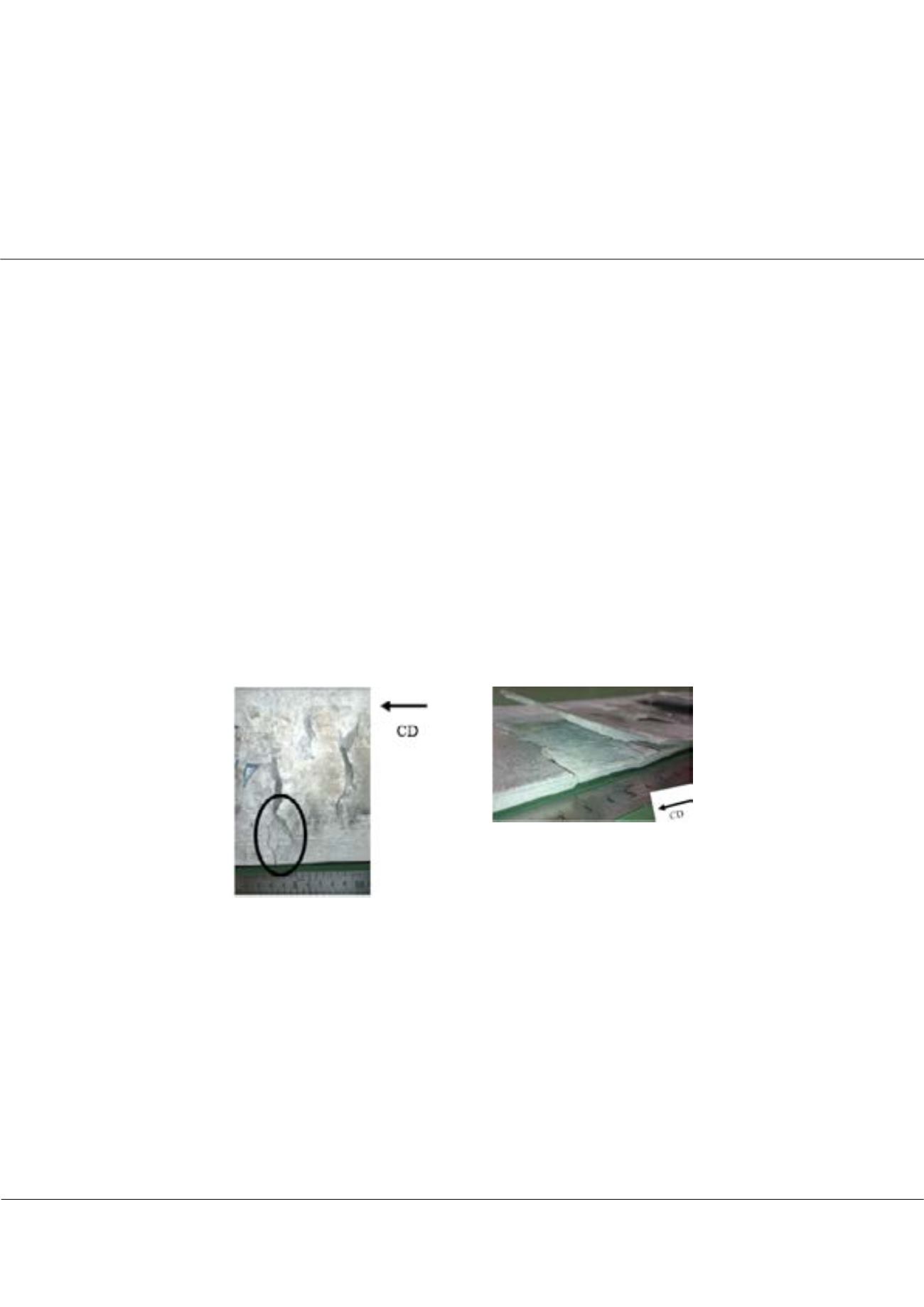

at pouring temperature 710°C. Solidification cracking occurred at a pouring temperature of 740°C. Generally, the strip thickness

tends to decrease as the pouring temperature increases. However, the strip thickness of pouring temperature of 710°C and 740°C

increased compared with the pouring temperature of 680°C. Moreover, the strip thickness decreased at the pouring temperature of

770°C. As a result of observing the microstructure, equiaxed crystals were produced at any pouring temperature.

(a) Cracks (Pouring temperature was 710°C)

(b) Cracks (Pouring temperature was 740°C)

Fig.1

Solidification cracks of produced A7075 aluminum alloy strip by twin roll caster

Recent Publications

1. Yuta Kashitani, Shinichi Nishida, Junshi Ichikawa, Hiroto Ohashi, Nao Ozawa, Ryosuke Okushima, Tomoya Suzuki,

Yuto Takigawa and Hideto Harada, Twin Roll Casting of Aluminium Alloy ADC12, A3003, A7075, Key Engineering

Materials, Vol.735, 18-23 (2017).

2. Hiroto Ohashi, Shinichi Nishida, Yuta Kashitani, Junshi Ichikawa, Nao Ozawa, Tomoya Suzuki, Ryosuke Okushima,

Atsuhiro Aoki and Hideto Harada, Direct Molten Metal Rolling of Aluminum Alloy A3003, Key Engineering Materials,

Vol.735, 13-17 (2017).

3. Yuta Kashitani, Shinichi Nishida, Junshi Ichikawa, Hiroto Ohashi, Nao Ozawa, Ryosuke Okushima, Tomoya Suzuki,

Yuto Takigawa and Hideto Harada, Twin Roll Casting of Aluminium Alloy ADC12, A3003, A7075, Key Engineering

Materials, Vol.735, 18-23 (2017).

Yuta Kashitani et al., Res. Rev. J Mat. Sci. 2018, Volume 6

DOI: 10.4172/2321-6212-C3-020