Page 41

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

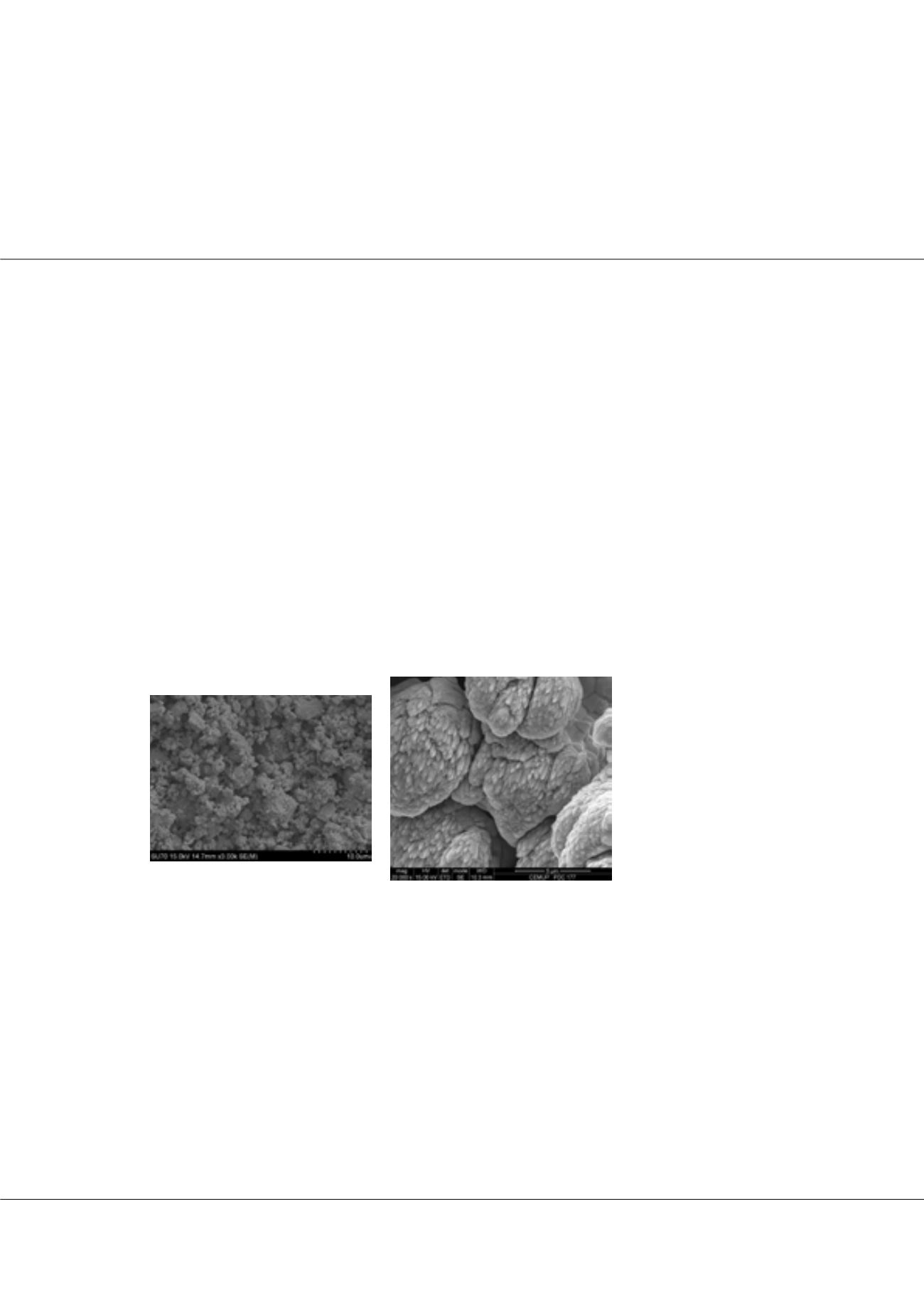

Design of nanostructured powders and mechanical properties of WC-AISI 304 stainless steel composites

Ana M.R. Senos

University of Aveiro, Portugal

C

emented carbides are constituted by WC and a metallic binder usually processed through powder metallurgy routes. The good

compromise between hardness and toughness achieved in cemented carbides designates the common use to cutting, machining

and wear applications. The increasing application demands require not only materials with improved properties but also efficient

processing techniques. The improvement of mechanical properties, namely hardness, can be achieved through grain size reduction

up to the nanoscale range. In the present work nanostructured powders of WC and stainless steel (SS) have been prepared using

two routes: high energy ball milling (HEBM) to produce nanometric particles of WC and SS; and an innovative sputtering coating

technique (SC) to coat micrometric WC particles with nanometric SS. For comparison, powders in the micro/submicrometer range

were also prepared by conventional milling (CM). Composites of these powders were shaped by pressing and thermal consolidated

using vacuum sintering. The final phase composition and microstructure were characterized by X-ray diffraction (XRD) and scanning

electron microscopy (SEM/EDS), respectively, together with X-ray mapping for elemental distribution and electron backscatter

diffraction (EBSD) for the grain size distribution. High resolution transmission electron microscopy (HRTEM) was also used for

grain boundaries inspection and access the nanometric details of the microstructure. Composites from the different powders (HEBM,

SC and CM) showed very different values of hardness, HV30, and toughness, KIC, varying from extremely hard parts for the HEBM

composites, to impressive high tough composites for the SC parts. These mechanical responses are discussed taking into account the

structure/microstructure and grain boundaries details leaded by the designed powder morphology.

Biography

Ana Senos is Associate Professor at the Dep. Materials and Ceramic Engineering, University of Aveiro, Portugal. She has been involved in the investigation of

ceramics and nanocomposites processing, on the topics of sintering kinetics, microstructural development, grain boundary design, constrained sintering, and the

relation with the electrical answer and mechanical behavior of materials. Current interests are focused on development of nanostructured materials for structural,

electrical and nuclear applications and on the study of grain boundary phenomena in electronic functional materials (2D, 3D), for microwave and energy applications.

Is author (co-authored) of more than 130 publications, including 3 Book Chapters, 103 papers (92 from SCI), 19 proceedings and 2 patents, with ca. 1400 citations

(h-index=22). She has about 130 communications as oral and poster presentations or as invited speaker.

anamor@ua.ptAna M.R. Senos, Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-005

SEM micrographs (a) WC-12SS

mixture prepared by HEBM; (b) WC

powder sputter-coated with 12SS.